HVAC systems play an essential role in both pharmaceutical manufacturing and hospital environments, ensuring clean, controlled air that safeguards patient health, product integrity, and compliance with stringent hygiene standards. In the GCC, where climate challenges such as high temperatures and dust storms add complexity to HVAC operations, designing compliant systems is even more critical. While pharmaceutical vs hospital HVAC systems share overlapping standards and similar goals for contamination control, key distinctions arise in filtration, pressure control, monitoring, and regulatory validation. This expanded article explores shared standards, major design differences, and best practices for achieving reliable HVAC performance across both sectors.

Discover our Hygienic AHUs for Hospitals engineered to meet the strict demands of both pharmaceutical and healthcare HVAC environments.

Shared Objectives of Pharmaceutical and Hospital HVAC

At their foundation, pharmaceutical vs hospital HVAC systems share critical objectives aimed at creating safe and sterile environments:

Air Cleanliness and Contamination Control: Both sectors demand ultra-clean air to reduce airborne contamination that could compromise drugs, treatments, or patient safety.

Infection and Cross-Contamination Prevention: Hospitals prevent hospital-acquired infections (HAIs), while pharma manufacturing prevents cross-batch contamination.

Stringent Indoor Air Quality Standards: IAQ standards define ventilation rates, filtration levels, humidity, and temperature control, ensuring a stable and contaminant-free environment.

Positive and Negative Pressure Control: Specialized spaces rely on controlled airflow and pressure differentials to contain or protect sensitive environments.

Regulatory Compliance: International standards like ISO, ASHRAE, and GMP guidelines require similar levels of precision in both sectors.

These shared principles result in overlapping engineering approaches for airflow design, filter placement, and environmental monitoring.

Download the free Preventive Maintenance Checklist for Hospital AHUs to ensure proper servicing and hygiene compliance in both healthcare and pharma environments.

Overlapping Standards and Guidelines

The regulatory landscape driving pharmaceutical vs hospital HVAC designs includes multiple international and regional standards:

ISO 14644: Specifies cleanroom classifications for particulate cleanliness. Both pharma production and hospital operating rooms aim for ISO Class 7 or better in critical zones.

ASHRAE Standards: Provide universal HVAC guidance for IAQ, ventilation, and comfort in healthcare and pharma facilities.

EU GMP Annex 1: Defines requirements for sterile drug manufacturing, influencing hospital pharmacy compounding and biotech treatment areas.

WHO GMP and CDC Guidelines: Ensure contamination control, sterile production, and infection prevention practices common to both sectors.

GCC Ministry of Health Regulations: Authorities in UAE, Saudi Arabia, and others enforce IAQ and pressure zoning requirements consistent with global guidelines.

These overlapping standards mean that pharmaceutical and hospital HVAC systems often share similar high-efficiency filtration, airflow patterns, and zoning strategies.

Learn how HEPA Filters in Healthcare HVAC support cleanroom and sterile hospital applications for maximum compliance.

Key Differences in HVAC Design and Operation

While objectives and standards overlap, significant differences define pharmaceutical vs hospital HVAC systems:

1. Filtration

Hospitals generally use HEPA filters (H13/H14) to protect patients in surgical theatres, ICUs, and isolation wards.

Pharmaceutical facilities frequently employ ULPA filters, capable of capturing finer particulates, to achieve ISO Class 5 or better for sterile manufacturing zones.

Pharma filter housings undergo validated zero-bypass leakage testing, exceeding standard hospital requirements.

2. Pressurization and Zoning

Hospitals typically manage single-level positive or negative pressure areas.

Pharmaceutical cleanrooms use cascade pressure zoning, progressively changing pressure levels across multiple adjacent spaces for contamination control.

Pharma zoning requires precise airflow balancing and more complex control systems than standard hospital zoning.

3. Humidity and Temperature Control

Pharma production lines demand tight humidity and temperature tolerances to maintain product stability.

Hospitals focus on patient comfort and infection prevention with broader environmental ranges.

Pharma AHUs incorporate advanced dehumidifiers and reheat coils for precise conditioning.

4. Air Changes per Hour (ACH)

Sterile pharma manufacturing often requires 20–30+ ACH to meet cleanroom classifications.

Hospitals maintain variable ACH: 20–25 in operating rooms, 6–12 in patient wards.

This results in higher and more consistent ventilation rates in pharma settings.

5. Validation and Monitoring

Pharma HVAC systems undergo extensive IQ/OQ/PQ qualification, continuous particle counting, and microbial monitoring.

Hospitals validate mainly high-risk zones like operating rooms and isolation rooms but with less stringent documentation compared to pharma facilities.

Pharma systems must document environmental compliance for every production batch, adding complexity.

6. System Redundancy and Scalability

Pharmaceutical facilities build redundancy into fans, filtration banks, and control systems to ensure uninterrupted cleanroom operation.

Hospitals, while robust, rarely match pharma redundancy levels except in critical areas like surgical suites or isolation wards.

Case Examples of Integrated Standards

Dual-use facilities in GCC regions highlight how pharmaceutical vs hospital HVAC standards converge:

Hospital Pharmacies and Labs: Often meet GMP-level standards for sterile compounding and cleanroom drug preparation.

Biotech Hospitals: Advanced therapy units for biologics or cell treatment operate under full GMP cleanroom conditions within hospitals.

Integrated ACS CLIMACS Solutions: Klima Global provides AHUs that meet ISO 14644 and GMP standards while also complying with ASHRAE healthcare guidelines, allowing facilities to operate across both domains.

These examples showcase the practicality and necessity of dual-compliant HVAC systems to meet modern healthcare and pharmaceutical demands.

Best Practices for Multi-Sector HVAC Design

Designing systems for pharmaceutical vs hospital HVAC applications requires an advanced, flexible approach:

Modular AHU Design: Use AHUs that can be configured for either HEPA or ULPA filters, validated seals, and redundant fan arrays.

Advanced Pressure Management: Implement cascade zoning and precision pressure sensors to meet both pharma and hospital requirements.

Certified Components: Employ Eurovent, TUV, and GMP-certified equipment suitable for dual-compliance projects.

Comprehensive Monitoring: Integrate real-time particle counters, IAQ sensors, and automated reporting systems for regulatory audits.

Lifecycle Validation: Include GMP qualification procedures and hospital environmental testing within project commissioning.

Expert Collaboration: Partner with experienced HVAC engineers like Klima Global who have proven expertise in healthcare and pharmaceutical facility design.

Following these best practices ensures robust contamination control, energy efficiency, and regulatory compliance for multi-sector environments.

Explore our comprehensive Healthcare HVAC Solutions tailored for hospitals and pharmaceutical facilities across GCC.

Summary: Balancing Standards for Pharma and Hospital HVAC

Advanced HVAC systems underpin safety, product integrity, and patient care in both pharmaceutical and hospital settings. While pharmaceutical vs hospital HVAC systems share standards for IAQ, filtration, and pressure control, they differ markedly in cleanroom classification, validation requirements, and environmental precision.

Working with Klima Global provides:

Certified ACS CLIMACS AHUs engineered for healthcare and pharma

Compliance Expertise with ISO 14644, GMP, ASHRAE, and GCC regulations

Proven Track Record delivering dual-compliant solutions across GCC projects

By understanding and balancing these differences, facilities can achieve clean, safe, and efficient environments for patients and pharmaceutical products alike.

Frequently Asked Questions (FAQ)

Can pharmaceutical cleanroom AHUs be used in hospitals?

Yes. They are often utilized in hospital pharmacies and biotech labs but may be over-engineered for general wards.

What is the main difference in filtration between pharmaceutical vs hospital HVAC?

Pharma uses ULPA filters with higher capture efficiency, while hospitals mainly rely on HEPA filters.

How do pressure differentials vary between the two sectors?

Pharma requires multi-stage cascade zoning, whereas hospitals manage single-zone positive or negative pressures.

Are there common international certifications for both industries?

Yes. ISO 14644 and ASHRAE guidelines apply to both, and GMP standards influence certain hospital areas.

How do validation requirements differ?

Pharma facilities demand full GMP qualification (IQ/OQ/PQ), while hospitals typically validate only high-risk zones.

Need dual-compliance HVAC solutions for healthcare or pharma projects?

Klima Global offers certified AHUs for both pharmaceutical and hospital applications across the GCC.

Get Expert Consultation NowShare this post

Related Posts

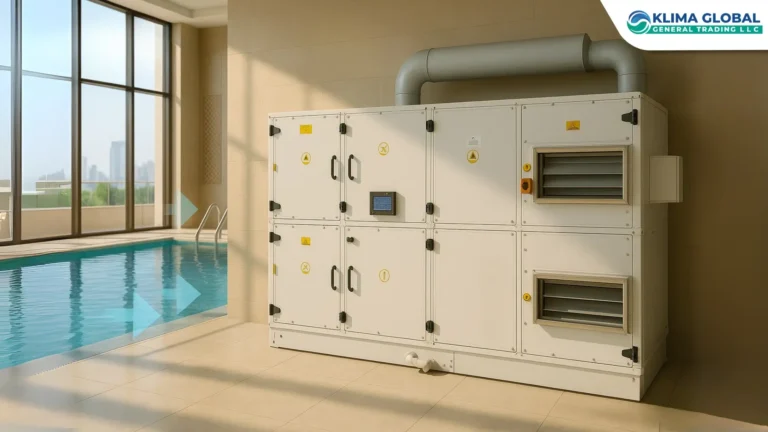

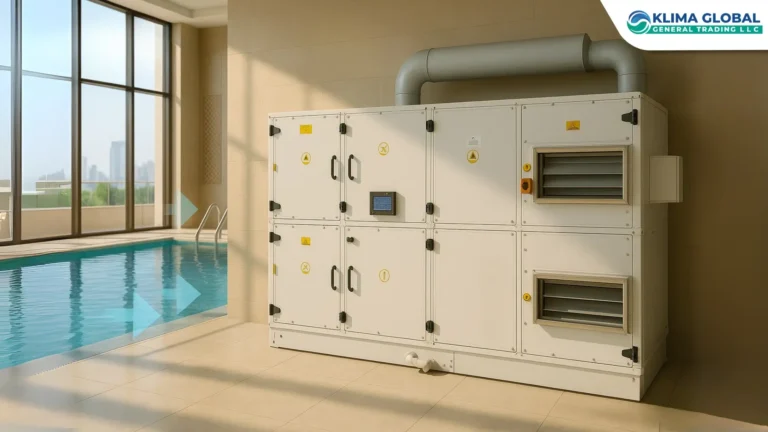

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global

Latest Posts

Fresh Air Handling Units: Components, Operation & Maintenance

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global