Walk into a hotel lobby in Dubai or a shopping mall in Riyadh and you feel instant relief from the heat. That comfort is not an accident. Early in design, engineers choose VAV vs CAV—two ways of moving air that shape energy bills, indoor comfort, and compliance for years. This article tells that story in simple language and shows how to choose the right approach for projects across the GCC.

Still torn between a central plant or distributed refrigerant? Dive into our UAE-specific VRF vs. Chiller comparison to see cost, comfort, and ROI side-by-side.

What Are VAV vs CAV Systems?

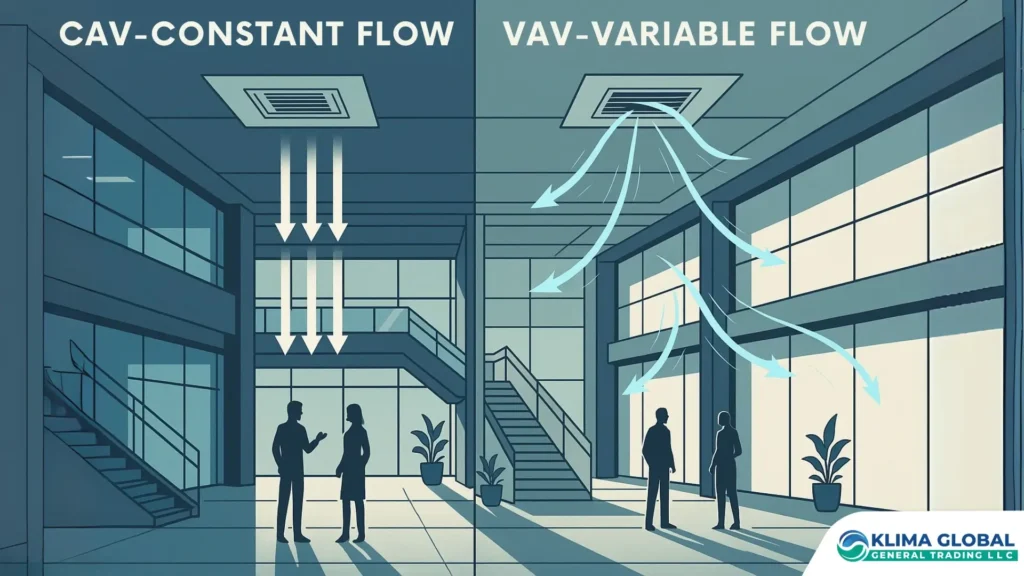

Both systems deliver conditioned air to a space. They just do it differently:

Constant Air Volume (CAV): The system supplies the same amount of air all the time. It changes the air temperature to meet the setpoint.

Variable Air Volume (VAV): The system changes how much air it supplies based on need. Supply air temperature is relatively steady; airflow varies.

Simple analogy: CAV is a ceiling fan locked at one speed. VAV is a smart fan that speeds up when a room fills up and slows down when it empties.

The CAV System: Reliable Simplicity

CAV is straightforward to design and install.

Strengths: Simple hardware, lower upfront cost, predictable operation, easy to maintain.

Best suited for: Small offices, classrooms, clinics, or single‑zone spaces with stable loads.

Trade‑offs: Fans run at full flow even when the space does not need it. That can waste energy and cause hot/cold spots in multi‑zone areas.

Picture a boardroom in Muscat—chilly at 10 a.m., stuffy by 3 p.m. The load changed, but the airflow didn’t. That’s classic CAV.

The VAV System: Smarter Comfort

VAV adapts airflow to the actual demand of each zone.

Strengths: Energy savings at part load, more stable comfort, excellent for multi‑zone buildings, easy to integrate with BMS and smart controls.

Best suited for: Malls, airports, hotels, hospitals, campuses, high‑rise offices.

Trade‑offs: Higher initial cost, more complex controls, needs proper commissioning and balancing.

Imagine a Doha shopping center—one store is packed, the next is quiet. VAV shifts air to where people are, in real time.

VAV vs CAV: Side‑by‑Side Comparison

| Factor | CAV System | VAV System |

|---|---|---|

| Airflow control | Constant volume | Variable volume per zone |

| Fan operation | Near constant speed | Variable speed (VFD) |

| Comfort | Adequate for single zone; uneven in multiple zones | Stable, tailored per zone |

| Energy at part load | Lower (fans at full flow) | Higher (fan turndown saves power) |

| Temperature strategy | Varies supply air temp | Holds supply temp, varies flow |

| Humidity handling | Basic | Better with reheat/controls |

| Upfront cost | Lower | Higher |

| Lifecycle cost | Higher in many multi‑zone uses | Lower with proper control |

| Controls complexity | Simple thermostats | VAV boxes, sensors, BMS |

| Commissioning need | Basic | Critical (setpoints, balancing) |

| Retrofit suitability | Good for small/simple | Good for large upgrades with BMS |

| Best applications | Small, steady‑load spaces | Large, diverse‑load buildings |

Why This Choice Matters More in the GCC?

Cooling dominates energy use in UAE, Saudi, Oman, Qatar, Kuwait, Bahrain. Systems run long hours at high outdoor temperatures. Design choices directly affect utility costs, comfort, and code compliance.

Codes & programs: Projects often target ASHRAE 90.1, Estidama, LEED, or local energy codes that favor efficiency.

Climate reality: High ambient temperatures and humidity magnify the value of part‑load efficiency and good dehumidification control.

Operational patterns: Malls, hotels, and airports see variable occupancy throughout the day—ideal for VAV’s adaptive airflow.

How VAV Saves Energy?

Fan power roughly scales with the cube of fan speed. If you can reduce fan speed by 20%, power can drop by about 50% (0.8³ ≈ 0.51). In real buildings, VAV systems lower airflow during off‑peak times across many zones, trimming fan energy and often reducing simultaneous reheat.

Example: A large mall in Dubai with 150 kW of supply fan power runs at an average of 80% speed during the day. Fan power ≈ 0.8³ = 51% of full power, cutting a large share of electricity compared with CAV at 100% flow. Actual results depend on design, controls, and schedule.

When CAV Still Wins?

CAV remains a good choice in specific cases:

Small, single‑zone projects with steady loads and tight budgets.

Spaces needing fixed airflow for process or pressure control, where simplicity is valued.

Retrofits where adding controls, sensors, or duct changes is impractical.

Design Essentials for a Successful VAV Project

VAV delivers value when design and commissioning are done right.

Right zoning: Group areas with similar loads (sun exposure, occupancy, hours). Avoid mixing a sunny façade with an interior core on one zone.

Minimum ventilation: Set and verify outdoor air per zone. Use CO₂ sensors or schedules where appropriate.

Static pressure reset: Use duct pressure sensors and VFDs to reset setpoints and prevent excess fan energy.

Supply air temperature (SAT) reset: Reset SAT based on load and humidity to balance coil and fan energy.

Reheat strategy: Limit reheat by improving zoning and supply air control. Avoid cooling then reheating the same air.

Diversity factor: Account for not all zones peaking at once; size thoughtfully.

Metering: Add sub‑meters for fans and reheat to verify savings.

Commissioning & Maintenance: VAV vs CAV

CAV commissioning is simple: verify flows, temperatures, and thermostats. Maintenance focuses on filters, coils, and fan belts/bearings.

VAV commissioning needs more steps:

Calibrate VAV boxes (min/max flow, damper response).

Balance zones and verify setpoints.

Tune control loops, static pressure reset, and SAT reset.

Test with realistic occupancy scenarios and schedules.

Ongoing maintenance for VAV:

Keep sensors clean and calibrated.

Maintain filters and coils to keep static pressure in check.

Review BMS trends quarterly to spot drift or stuck dampers.

VAV vs CAV: Comfort, IAQ, and Humidity

Comfort: VAV shines in mixed‑use buildings because it adapts to uneven loads. CAV can be comfortable in single zones but struggles where demands vary.

IAQ: Both systems can meet ventilation codes. VAV needs careful minimum flow settings to sustain fresh air in each zone even at low demand.

Humidity: In humid coastal cities, VAV plus good SAT control and reheat can better manage latent loads than CAV at fixed flow.

Wondering which unit belongs in your design? See FAHU vs. AHU — the key differences for GCC projects(with when-to-choose checklists).

Budget vs Lifecycle: Making the Business Case

Upfront: CAV is cheaper to buy and install. VAV costs more due to boxes, sensors, and controls.

Operational: VAV typically cuts fan energy and reduces simultaneous heating/cooling, improving lifecycle cost.

Compliance & incentives: Efficient designs can help achieve Estidama/LEED points and meet owner sustainability targets.

Tip: Build a simple ROI model with: incremental capex, expected fan energy reduction, reheat changes, utility tariffs, and maintenance assumptions. Even a conservative model helps align stakeholders.

VAV vs CAV: Quick Decision Path

Is the project multi‑zone with variable occupancy? If yes, lean VAV.

Is the project small or single‑zone with stable loads? If yes, consider CAV.

Is lifecycle cost and compliance a priority? If yes, lean VAV.

Is first cost the main constraint and simplicity key? If yes, consider CAV.

Common Pitfalls and How to Avoid Them

Oversized minimum flows on VAV boxes → high fan energy and noise. Fix: Set realistic mins; enable diversity and pressure reset.

Poor zoning → hot/cold complaints. Fix: Group by solar gain, occupancy, and hours.

No SAT or pressure reset → lost savings. Fix: Implement and tune resets in the BMS.

Uncalibrated sensors → hunting and discomfort. Fix: Calibrate on a schedule and trend key points.

VAV vs CAV: Mini Case Snapshot

A 40,000 m² mixed‑use tower in Abu Dhabi converted selected CAV floors to VAV during a renovation. With pressure and SAT reset, BMS trending, and right zoning, the operator observed meaningful fan energy reductions and improved comfort. The team scheduled quarterly reviews to keep performance on track. Results vary by project; commissioning quality is critical.

The Future of Airflow in the GCC

Comfort across every corner of a building comes from smart airflow decisions. In a region where cooling is mission‑critical, choosing VAV vs CAV influences comfort, cost, and compliance for decades.

At Klima Global, we help consultants, engineers, and facility managers weigh trade‑offs and design systems that perform from day one—then keep performing.

Planning a project in the GCC? Get a consultant‑ready comparison or a quick ROI view tailored to your building. Contact Klima Global to start the conversation.

Get Customized solution for your Project!

Share this post

Related Posts

Energy Recovery Ventilation Unit Supplier in UAE & GCC

Ecology Unit Supplier in Saudi Arabia and UAE

Latest Posts

Laminar Flow Unit Supplier in UAE & GCC

Energy Recovery Ventilation Unit Supplier in UAE & GCC

Ecology Unit Supplier in Saudi Arabia and UAE