Understanding Fresh Air Handling Units (FAHUs): Components, Operation, and Maintenance

Fresh Air Handling Units (FAHUs) are dedicated ventilation systems that bring 100% outdoor air into a building, filter it through multi‑stage filtration, condition it for temperature and humidity, and distribute it evenly to occupied spaces. In hot–humid climates like the UAE and wider GCC, Fresh Air Handling Units are essential for Indoor Air Quality (IAQ), comfort, and code compliance. This article explains FAHU construction and design, core components, how the units operate, recommended maintenance practices, and where FAHUs fit within regional standards and applications.

Related reading – For a system‑level perspective on whole‑building air distribution, see our product overview: Air Handling Unit (AHU) options and configurations. Explore solutions: Air Handling Unit – CLIMACS

What is a Fresh Air Handling Unit (FAHU)?

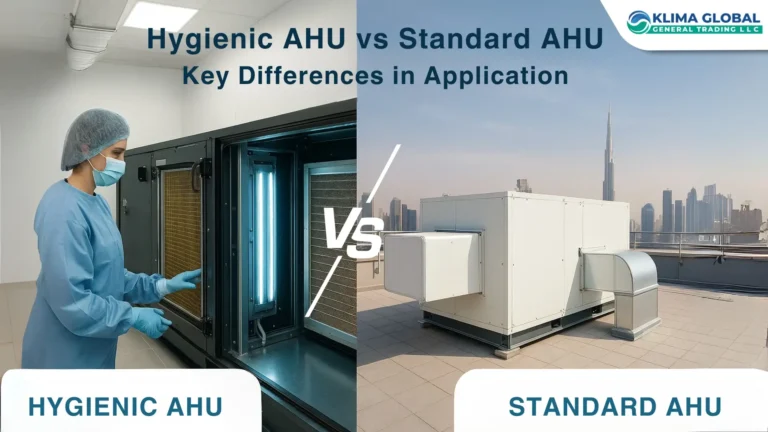

A FAHU is a purpose‑built air handler that processes only outdoor air. Unlike a conventional AHU (which often mixes return air with fresh air), a FAHU maintains ventilation rates and contaminant control by delivering treated, pressurised fresh air to the supply ductwork. This is crucial in healthcare, hospitality, education, and high‑occupancy commercial buildings where ventilation and hygiene requirements are stringent.

FAHU vs AHU in one glance

FAHU: 100% fresh air, multi‑stage filtration, humidity control as required, typically higher outdoor load management.

AHU: Supplies mixed air (return + fresh), optimized for space conditioning with recirculation.

Go deeper – Understand when to specify each system and how they complement each other in design. Read comparison insights: FAHU vs AHU, what are the differences?

Key Construction and Design Features of Fresh Air Handling Units

Double‑skin casing & insulation

Sandwich panels (typically 25–50 mm) with acoustic/thermal insulation reduce casing losses and mitigate condensate formation—vital for outdoor air treatment in high humidity.Modular sections

Standardized sections (intake & dampers, filtration, cooling/heating coils, humidification, fan chamber) simplify selection, transport, installation, and service access.Sealing & hygiene

Gasketed access doors, smooth internal surfaces, and sloped drain pans support hygienic operation and easy cleaning.Fan isolation & vibration control

Anti‑vibration mounts and flexible connections protect the casing and reduce noise transmission to ducts.Controls & instrumentation

Differential pressure ports/sensors across filters and coils, temperature & humidity sensors, and interface with BMS/PLC for setpoint control and fault monitoring.

Healthcare note – For infection control and sterile environments, pair Fresh Air Handling Units with terminal HEPA zones and UV‑C strategies. Explore application detail: UV‑C Air Purification in Hospital HVAC

Main Components of FAHUs

1) Air Filtration

A typical FAHU uses multi‑stage filtration to remove dust, sand, pollen, and fine particulates before air enters the occupied zone.

Pre‑filters (ISO Coarse) extend life of downstream filters and protect coils.

Fine filters (ePM1/ePM2.5/ePM10) target small particulate for IAQ compliance.

HEPA (optional) for critical spaces (OTs, labs, pharma) typically housed in terminal boxes or dedicated hygienic sections.

Good practice: Size filters for low face velocity to reduce pressure drop; include DP monitoring and service clearance.

2) Cooling & Heating Coils

Cooling: Chilled‑water or DX coils handle sensible + latent loads from hot‑humid outdoor air; coil rows and fin spacing are selected for target SHR and dew‑point control.

Heating/Reheat: Hot water, steam, or electric coils prevent over‑cooling and manage post‑dehumidification RH.

Good practice: Use corrosion‑resistant drain pans, adequate access for coil cleaning, and droplet eliminators where required.

3) Humidification Section (as needed)

Where indoor RH must be maintained within a specific band (e.g., healthcare, museums), integrate steam injection or adiabatic humidifiers with drift eliminators and proper control logic.

4) Fan & Motor Assembly

High‑efficiency centrifugal or EC/plug fans with VFDs deliver the required airflow at the designed external static pressure (ESP) while minimizing energy use and noise. Include backdraft dampers where shutdown backflow is a risk.

5) Drainage, Access & Serviceability

Insulated, sloped drain pans (with trapped drain lines), large service doors, internal lighting, and viewing ports support routine inspection, cleaning, and verification of coil and filter condition.

Design checklist – Selecting an AHU or FAHU for a project? See the five critical parameters to review before submittals. Read the guide: 5 Factors Before Choosing an AHU

Operating Principles of Fresh Air Handling Units

Intake & Dampers – Outdoor air passes through weather louvres and motorized dampers that control volumetric flow and provide shutoff.

Filtration – Air moves through staged filtration to remove particulates and protect equipment and occupants.

Cooling/Dehumidification – Coils lower temperature below the air’s dew point to remove moisture; reheating may be applied to reach supply temperature without over‑cooling.

Humidification (if required) – Steam or adiabatic systems add moisture for setpoint control.

Supply via Fan Section – Fans deliver conditioned fresh air to the duct network at the design ESP; controls modulate fan speed for occupancy and pressure stability.

Ventilation strategy – In projects with high fresh‑air ratios, an HRV/energy‑recovery section can significantly reduce cooling loads. Context & case uses: Fresh Air Handling Units in Bahrain

Technical Specifications Overview (Typical Ranges)

The exact ratings depend on model and project selection. Typical FAHU envelopes for GCC projects:

| Parameter | Typical Range |

|---|---|

| Airflow | 1,000 – 50,000 m³/h (select models beyond) |

| External Static Pressure | 300 – 1,000 Pa |

| Cooling Capacity | Sized per coil rows/FPI; latent‑heavy dehumidification |

| Fan/Motor Input | ~0.75 – 55 kW depending on duty |

| Filtration | ISO Coarse pre‑filters + ePM1/ePM2.5 fine filters; HEPA optional |

| Humidity Control | Steam/adiabatic humidifiers (as required) |

| Controls | BMS/PLC integration, DP sensors, temperature & RH sensors |

System synergy – For packaged outdoor conditioning of zones (hallways, rooftops), evaluate complementary rooftop units within the same project. See options: Rooftop Units – CLIMACS

Maintenance Practices for Fresh Air Handling Units

Correct maintenance preserves IAQ, keeps energy use in check, and prevents unplanned downtime. Adopt a preventive schedule with documented service cards.

Weekly

Check condition of pre‑filters and fine filters; clean or replace if pressure drop is high.

Listen for abnormal fan noise and verify air paths are clear.

Monthly

Inspect belt & pulley mechanisms (if belt‑driven) and tension.

Verify drain pan cleanliness and unobstructed drainage; check traps/primers.

Inspect coils; wash if fouled.

Check access door gaskets, hinges, and latches for sealing integrity.

Every 6 Months

Measure motor operating current and compare with nameplate.

Inspect fan & motor bearings for noise/overheating.

Test operation of control instruments (sensors/switches).

Inspect humidifier pumps, strainers, and nozzles; remove scale.

Clean condensate lines; treat for biofilm if needed.

Annual

Reseal filter frame insulation; replace pre‑filters/fine filters per DP trend.

Straighten bent coil fins; leak‑check coils and repair if required.

Replace fan/motor belts (if belt‑driven) and torque‑check fasteners.

Lubricate bearings where not permanently lubricated.

Function‑test dampers for full stroke and shutoff.

Safety first – Always isolate power (LOTO), use qualified personnel, and follow original IOM procedures during service.

Further reading – For negative‑pressure isolation and pressure zoning concepts in healthcare projects, see our primer. Learn the essentials: Negative Pressure Rooms – HVAC Design

Importance of Fresh Air Handling Units in UAE & GCC Projects

IAQ & Comfort: FAHUs maintain outdoor air change rates and dilute contaminants, supporting occupant health and productivity.

Compliance: Designs align with ASHRAE ventilation principles and regional frameworks (e.g., Estidama, LEED) when properly selected and commissioned.

Energy & Reliability: Double‑skin construction, high‑efficiency fans, variable speed control, and (optionally) energy recovery all reduce lifecycle cost while maintaining robust performance in sand, heat, and humidity.

Regional application – For procurement considerations and specification cues, review market notes and project insights. Read more: FAHU Supplier – Qatar Perspective

Conclusion

Fresh Air Handling Units ensure that buildings receive the right quantity and quality of outdoor air—filtered, dehumidified, and delivered at stable pressure and temperature. By understanding FAHU construction, components, operating sequence, and maintenance routines, design teams and facility managers in the UAE & GCC can deliver healthier, compliant, and energy‑aware buildings.

Frequently Asked Questions (FAQ)

What is the biggest difference between a FAHU and an AHU?

A FAHU conditions only outdoor air, ensuring minimum ventilation rates and filtration. An AHU typically conditions a mix of return and fresh air to meet space loads.

How often should I replace filters in Fresh Air Handling Units?

Monitor differential pressure and environment. As a rule of thumb: check pre‑filters monthly; fine filters quarterly; HEPA (if used) every 6–12 months or per DP trend.

Do Fresh Air Handling Units reduce energy efficiency compared to recirculating AHUs?

Ventilating hot‑humid air adds load, but FAHUs can remain efficient via double‑skin casings, EC/VFD fans, optimized coils, and optional energy recovery to lower chiller burden.

Where are FAHUs commonly specified in UAE projects?

Hospitals, hotels, malls, schools/universities, and high‑occupancy commercial buildings where code‑mandated ventilation and IAQ standards apply.

What makes a FAHU “hygienic”?

Smooth internal surfaces, sealed access doors, sloped drain pans, appropriate filtration, and maintenance‑friendly layouts. In critical areas, pair with terminal HEPA and UV‑C.

Share this post

Related Posts

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global

Latest Posts

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global