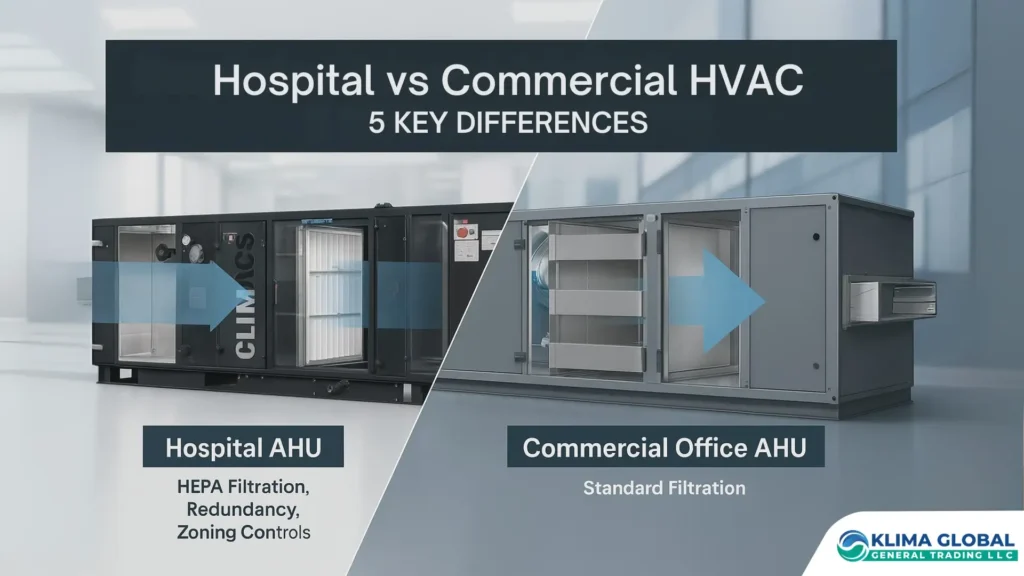

Hospital vs Commercial HVAC: 5 Key Differences Engineers Should Know

In the GCC region—where extreme heat, humidity, and dust storms are common—hospital vs commercial HVAC systems are engineered with vastly different objectives. Indoor air quality (IAQ) and precise temperature control are critical in any building environment, but in hospitals, the stakes are exponentially higher. Hospitals must maintain sterile environments, prevent infection spread, and meet stringent healthcare regulations. This extended guide explores the 5 major differences between hospital and commercial HVAC systems that every engineer and facility manager should understand to design and operate safe, reliable healthcare environments.

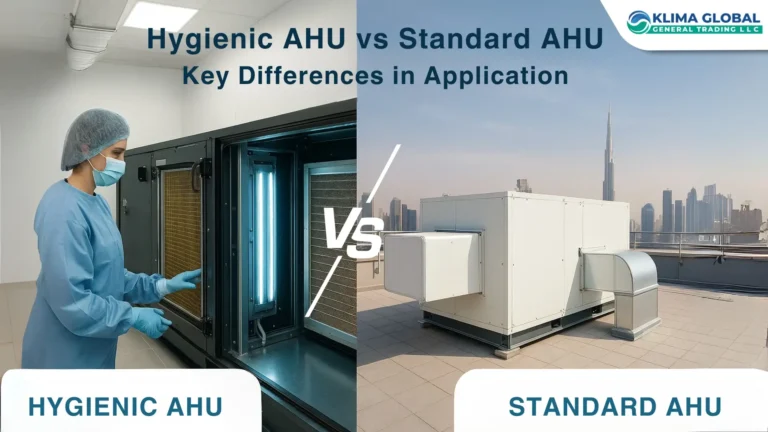

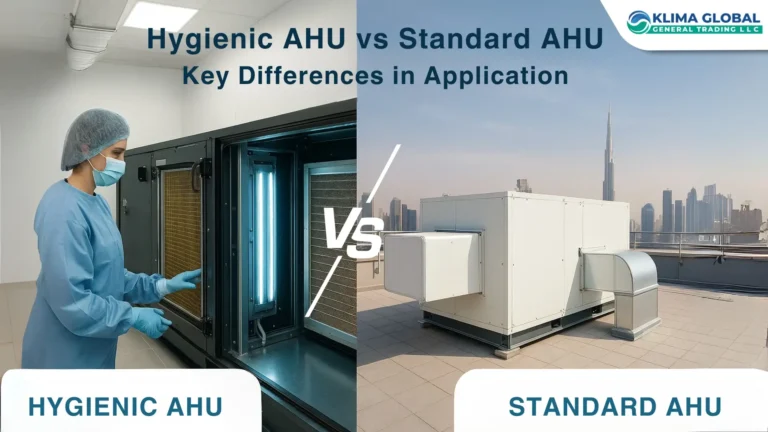

Discover how advanced Hygienic AHUs for Hospitals are engineered to meet the strict demands of GCC healthcare facilities.

1. Hygiene and Air Filtration Standards

Hospitals demand significantly higher hygiene and air filtration standards compared to commercial buildings. Hospital vs commercial HVAC systems differ primarily in their filtration technology and hygiene focus:

Hospitals utilize multi-stage filtration, including G4 (coarse), F7 (fine), and HEPA H13/H14 filters to capture airborne bacteria, viruses, and particulates.

Commercial HVAC systems generally use filters rated MERV 8–13, suitable for comfort cooling but not sterile environments.

Infection control guidelines (ASHRAE 170, HTM 03-01) mandate hygienic AHUs designed for clinical cleanliness and contaminant-free airflow.

ACS/CLIMACS Hygienic AHUs from Klima Global are tailored for hospital-grade filtration, meeting GCC healthcare standards and helping reduce hospital-acquired infections.

Additionally, hospital HVAC systems often integrate UV-C light sterilization and antimicrobial coatings to further enhance indoor air hygiene. This layer of protection is unnecessary in commercial buildings but vital in hospitals where vulnerable patients require exceptionally clean environments.

Learn more about HEPA Filters in Healthcare HVAC and their critical role in maintaining hospital air quality and safety.

2. Pressure Control and Zoning

Another critical difference between hospital vs commercial HVAC systems is the use of strict pressure control and zoning strategies:

Hospitals maintain positive pressure in operating rooms to push contaminants out and negative pressure in isolation wards to contain infectious particles.

Specialized areas like ICUs, labs, and cleanrooms require independent pressure control and zoning to ensure clean airflow and contamination prevention.

Commercial buildings rarely implement such differential pressurization; they focus on maintaining general comfort without infection risk considerations.

Hospital HVAC units incorporate pressure sensors, controlled airlocks, and advanced dampers to manage airflow between multiple sensitive zones.

Proper zoning and pressure gradients are continuously monitored and adjusted using sophisticated BMS systems to minimize cross-contamination and improve patient safety.

3. Redundancy and Reliability

Downtime in healthcare HVAC systems can be life-threatening, making redundancy and reliability crucial design priorities. In hospital vs commercial HVAC systems, this difference is evident:

Hospitals feature redundant AHUs, dual-fan setups, parallel duct networks, and dedicated backup power supplies to ensure uninterrupted operation.

Critical spaces like surgical suites and ICUs often have multiple air handling units operating simultaneously to handle peak loads or failure scenarios.

Commercial buildings typically operate with single points of failure and are designed for less demanding continuous operation.

ACS/CLIMACS hospital-grade AHUs integrate fault-tolerant designs with alarms and emergency operation modes to comply with healthcare resilience requirements.

This level of redundancy ensures consistent air quality and thermal comfort even during power outages or component failures, an essential factor in maintaining safe, sterile hospital environments.

4. Ventilation Rates and Air Changes

Hospitals require significantly higher ventilation rates and air changes than commercial buildings to control contaminants and ensure healthy environments:

Operating rooms in GCC hospitals often demand 20–25 Air Changes per Hour (ACH) to meet ASHRAE 170 and local codes.

Isolation rooms, treatment areas, and recovery wards each have specific ACH requirements tailored to their infection control needs.

Commercial offices, meanwhile, typically operate with 4–8 ACH focused solely on thermal comfort.

Hospital HVAC systems require larger fans, specialized ductwork, and carefully designed supply and exhaust pathways to deliver these higher ventilation rates efficiently.

High ACH levels influence energy consumption and fan power requirements. Modern hospital AHUs employ energy recovery systems and variable speed drives to maintain compliance while minimizing operational costs.

5. Controls and Monitoring

The level of control and monitoring in hospital vs commercial HVAC systems differs dramatically:

Hospitals deploy advanced Building Management Systems (BMS) with real-time IAQ sensors, pressure alarms, and automated balancing.

These systems provide continuous data logging, remote monitoring, and predictive maintenance capabilities to prevent failures and non-compliance.

Commercial HVAC systems generally use simpler thermostatic controls and basic environmental sensors without critical safety integrations.

In hospitals, controls are closely integrated with infection prevention protocols, surgical schedules, patient isolation procedures, and emergency ventilation modes.

This enhanced monitoring ensures that hospital HVAC systems meet rigorous standards consistently, allowing quick responses to emergencies or environmental changes.

Summary of Differences in Hospital vs Commercial HVAC Systems

Filtration: Multi-stage HEPA filters with antimicrobial protection vs basic commercial comfort filters.

Pressure Control: Positive/negative zoning with real-time monitoring vs neutral airflow zones.

Redundancy: Fault-tolerant, multi-unit setups designed for continuous operation vs minimal redundancy.

Ventilation Rates: 20–25 ACH with specialized ductwork vs 4–8 ACH for comfort.

Controls: Sophisticated BMS with IAQ, pressure monitoring, and predictive maintenance vs basic thermostatic systems.

For tailored solutions, explore our Healthcare HVAC Solutions designed to optimize air handling in medical environments.

| Feature | Hospital HVAC | Commercial HVAC |

|---|---|---|

| Filtration | G4, F7, HEPA H13/H14 + UV-C sterilization | MERV 8–13 |

| Pressure Zones | Positive/Negative differential zones | Typically unzoned |

| Redundancy | Dual-fan, parallel AHUs, backup power | Single units, minimal backups |

| Air Changes per Hour | 20–25 ACH, zone-specific ventilation | 4–8 ACH |

| Controls & BMS | Real-time IAQ, pressure monitoring | Basic thermostat, limited sensors |

Frequently Asked Questions (FAQ)

Why can’t standard commercial AHUs be used in hospitals?

Commercial AHUs lack HEPA filtration, redundancy, and infection control features needed for healthcare environments.

What is the minimum ACH requirement for GCC hospital operating rooms?

Typically 20–25 ACH is required to maintain sterile surgical conditions in compliance with ASHRAE 170.

How do pressure-controlled zones reduce infection risk?

Positive pressure keeps contaminants out of sterile rooms, while negative pressure isolates infectious areas to prevent cross-contamination.

What certifications should hospital HVAC systems have?

Systems should meet ASHRAE 170, HTM 03-01, and carry Eurovent/TUV certifications for hygienic AHUs.

What role does UV-C sterilization play in hospital HVAC?

UV-C sterilization helps deactivate microorganisms on coils and in ductwork, adding another layer of infection prevention.

Designing or upgrading HVAC for hospitals in the GCC?

Klima Global provides certified Hygienic AHUs, HEPA filtration systems, and engineering support tailored to healthcare facilities.

Get Expert Advice NowShare this post

Related Posts

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global

Latest Posts

Fresh Air Handling Units: Components, Operation & Maintenance

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global