Hygienic AHU: Ensuring Hospital Air Quality in GCC

Maintaining high indoor air quality (IAQ) in hospitals is crucial for infection prevention and patient safety. Across the GCC region—including the UAE, Saudi Arabia, Qatar, and Oman—healthcare facilities face unique challenges such as high dust levels, humidity, and strict regulatory standards. A Hygienic AHU (Air Handling Unit) plays a pivotal role in controlling airborne contaminants, ensuring sterile airflow, and supporting advanced infection control measures.

In modern healthcare infrastructure, a Hygienic AHU is not just an HVAC component—it is a compliance requirement and a key element in sustainable hospital design. Hospitals rely on these specialized AHUs to maintain pressurization, filter airborne pathogens, and meet international standards like ASHRAE 170 and ISO 14644.

As a leading supplier of Hygienic AHUs in GCC, Klima Global, through its ACS CLIMACS solutions, has successfully equipped numerous hospitals and healthcare facilities with state-of-the-art systems tailored for the region’s demanding climate. This article explores everything hospital engineers and facility managers need to know about Hygienic AHUs, from design features and standards to maintenance and energy efficiency, helping them make informed decisions for their next healthcare project.

What is a Hygienic AHU?

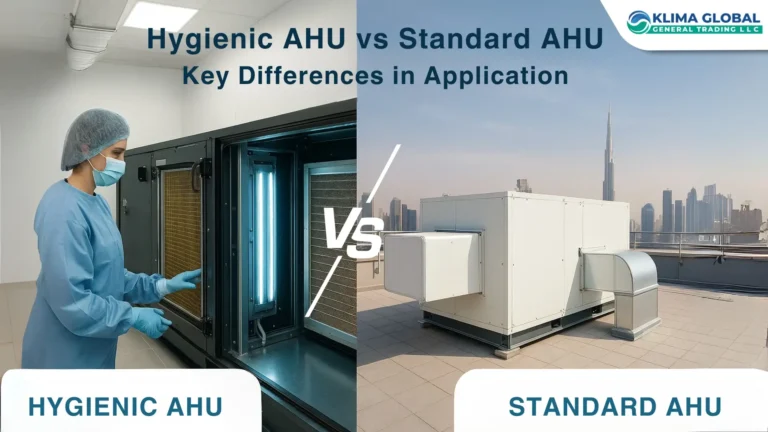

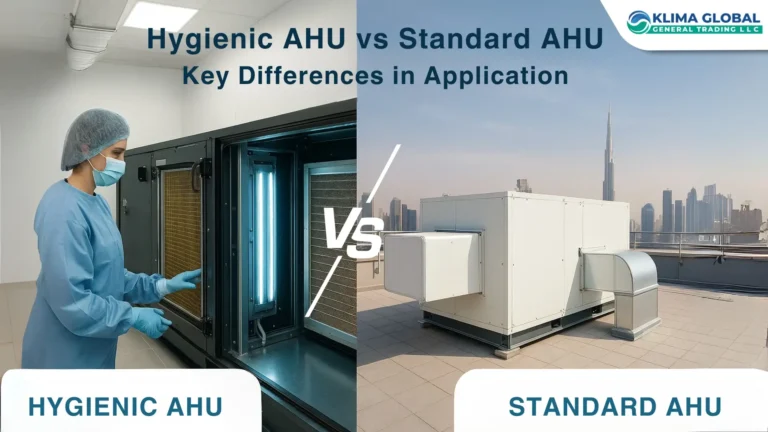

A Hygienic AHU is a specialized air handling unit designed specifically for clean and sterile environments like hospitals, laboratories, and pharmaceutical facilities. Unlike standard AHUs, Hygienic AHUs are engineered to meet stringent infection control and air quality standards required in medical settings.

Key differentiators include:

Double-skin insulated panels with thermal breaks to prevent condensation and microbial growth.

Anti-microbial coatings and seamless internal surfaces for easy cleaning and sanitation.

Multi-stage filtration systems incorporating pre-filters, fine filters, and high-efficiency HEPA filters for particle and pathogen removal.

UV-C sterilization modules for coil disinfection and air sterilization.

Hygienic drain pans with proper slopes and antimicrobial treatments to prevent standing water.

Airflow design and pressure control ensuring contamination-free air supply and proper pressurization in hospital zones.

These design features enable a Hygienic AHU to deliver clean, contaminant-free air, minimize infection risks, and comply with international ventilation standards, making it essential for operating theatres, ICUs, and isolation wards in GCC hospitals.

Why Hospitals in GCC Need Hygienic AHU

Hospitals in the GCC face unique environmental and operational challenges that demand specialized air handling solutions. A Hygienic AHU is essential due to:

Dust and Sand: Desert environments lead to high airborne particle levels that can compromise sterile hospital conditions without proper filtration.

Humidity and Heat: High temperatures and humidity in GCC countries create ideal conditions for microbial growth, making hygienic design critical.

Infection Control: Hospitals must protect vulnerable patients from airborne pathogens and maintain sterile environments in operating rooms and ICUs.

Regulatory Requirements: GCC health authorities like UAE’s DHA and Saudi MOH mandate advanced filtration and ventilation systems for hospitals.

Energy Efficiency Needs: With high cooling demands, hospitals require AHUs that combine hygiene with energy-saving features such as VFDs and heat recovery systems.

By addressing these challenges, a Hygienic AHU ensures safe, comfortable, and regulation-compliant indoor air environments tailored to the GCC’s demanding climate.

Key Features of Hygienic AHU for Hospitals

A Hygienic AHU must be designed with specific features to meet the high standards required in medical facilities:

Multi-Stage Filtration: Incorporates pre-filters, fine filters, and high-efficiency HEPA filters to remove dust, bacteria, and airborne pathogens effectively.

UV-C Sterilization: Built-in UV-C lamps sterilize coils and airflow, preventing microbial growth and ensuring clean air delivery.

Thermal Breaks: Prevent condensation and microbial accumulation, maintaining system hygiene.

Antimicrobial Surfaces: Internal surfaces are coated with antimicrobial materials and designed with rounded edges for easy cleaning.

Hygienic Drain Pans: Sloped and antimicrobial-treated drain pans to avoid standing water and bacterial growth.

Airflow and Pressure Controls: Integrated sensors and controls to manage airflow rates and maintain proper pressurization for different hospital zones.

Noise Control Measures: Low-noise fans and insulated panels to ensure patient comfort in sensitive medical areas.

These features work together to deliver a Hygienic AHU capable of providing contaminant-free, regulated air in high-risk hospital areas, ensuring patient safety and compliance with GCC healthcare standards.

Standards and Guidelines for Hygienic AHUs in Hospitals

Hygienic AHUs must meet strict standards and guidelines to ensure patient safety and regulatory compliance in GCC hospitals. These standards define requirements for air filtration, pressure control, airflow rates, and equipment hygiene.

ASHRAE 170: Specifies minimum ventilation rates, pressurization, and filtration standards for healthcare facilities.

ISO 14644: Defines cleanroom classifications that guide AHU filtration and airflow design for sterile environments.

HTM 03-01: UK standard for healthcare ventilation emphasizing hygiene, safety, and energy efficiency.

EN 1886 and EN 13053: European standards covering mechanical performance and energy efficiency of AHUs.

GCC Health Authority Regulations: UAE’s DHA and Saudi MOH mandate advanced filtration and hygienic designs for hospital HVAC systems.

Compliance with these standards ensures a Hygienic AHU delivers safe, clean, and energy-efficient air handling suitable for operating rooms, ICUs, isolation wards, and other critical healthcare zones.

Understand overlapping compliance requirements with our detailed guide on Pharmaceutical vs Hospital HVAC Standards, tailored for GCC healthcare and pharma projects.

Read HVAC Standards GuideApplications of Hygienic AHUs in Hospitals

A Hygienic AHU plays a vital role in multiple hospital departments, ensuring clean and controlled airflow for diverse medical environments. Its applications span critical and general areas to maintain patient safety and infection prevention:

Operating Rooms: Delivers high air changes per hour (ACH), HEPA-filtered airflow, and precise pressure control to maintain sterile surgical conditions.

Intensive Care Units (ICUs) and NICUs: Provides contaminant-free air, stable temperature, and humidity control for vulnerable patients.

Isolation Wards and Negative Pressure Rooms: Maintains negative pressure to contain infectious diseases and prevent cross-contamination.

Laboratories and Pharmacies: Ensures particle-free, filtered air for cleanroom environments required in medical testing and pharmaceutical compounding.

Radiology and Diagnostic Areas: Offers stable air quality and temperature control for sensitive medical equipment.

Outpatient Clinics and Surgical Centers: Maintains patient comfort and high IAQ standards even in high-traffic healthcare settings.

Using a Hygienic AHU in these areas ensures compliance with GCC healthcare regulations, supports infection control strategies, and improves overall hospital environmental safety.

Infection Control and Air Quality Management

Infection control is one of the primary reasons why hospitals in the GCC invest in Hygienic AHUs. These specialized air handling units are designed to minimize the risk of airborne infections and maintain optimal indoor air quality (IAQ) across various hospital zones.

Key aspects include:

HEPA Filtration: Removes up to 99.97% of airborne particles, including bacteria and viruses, crucial for sterile environments such as operating rooms and isolation wards.

UV-C Sterilization: Integrated UV-C lamps help disinfect coils and neutralize pathogens in the air stream, enhancing infection control.

Pressure Zoning: Maintains positive pressure in clean areas and negative pressure in isolation rooms to prevent cross-contamination.

Controlled Air Changes: Adequate air change rates dilute airborne contaminants, ensuring continuous removal of harmful particles.

Real-Time Monitoring: Advanced sensors track IAQ parameters like particulate levels, humidity, and temperature, ensuring compliance with healthcare standards.

A Hygienic AHU equipped with these features supports stringent infection control protocols, protecting patients, staff, and visitors from airborne health risks.

Enhance your hospital’s infection control strategy with advanced UV-C Air Purification solutions designed for GCC medical facilities.

Strengthen infection control in your healthcare facility with specialized Negative Pressure Rooms designed to contain airborne contaminants in GCC hospitals.

Learn About UV-C PurificationExplore Negative Pressure RoomsEnergy Efficiency and Sustainability in Hygienic AHUs

In addition to providing sterile and safe indoor environments, a Hygienic AHU must also support energy efficiency and sustainability. Hospitals in the GCC operate HVAC systems year-round due to high temperatures and humidity, making energy management critical for cost savings and environmental compliance.

Key energy-efficient and sustainable features of a Hygienic AHU include:

Variable Frequency Drives (VFDs): Adjust fan speeds based on real-time demand, reducing energy consumption without compromising airflow quality.

Heat Recovery Systems: Use energy recovery wheels or plates to reclaim cooling energy from exhaust air, improving overall system efficiency.

Demand-Controlled Ventilation: Automatically adjusts airflow based on occupancy and IAQ sensors, ensuring optimal ventilation rates.

High-Efficiency Motors: Utilize advanced motor technology that reduces power consumption and extends equipment lifespan.

Green Certifications: Designed to meet sustainability benchmarks like Estidama and DEWA energy standards for GCC hospitals.

Optimized Coil Design: Enhances heat transfer efficiency and reduces energy loss.

By integrating these technologies, hospitals can significantly reduce operating costs while achieving their sustainability goals. A modern Hygienic AHU not only protects patient health but also contributes to energy conservation and environmental stewardship.

Hygienic AHU Selection Criteria for GCC Hospitals

Selecting the right Hygienic AHU is crucial for achieving optimal air quality and compliance in healthcare environments. Hospitals in the GCC region should consider the following criteria when evaluating hygienic air handling units:

Airflow Capacity: Ensure the AHU can handle the required volume of air changes per hour (ACH) for critical hospital zones such as operating rooms, ICUs, and isolation wards.

Filtration Requirements: Choose multi-stage filtration with pre-filters, fine filters, and HEPA or ULPA filters based on hospital cleanliness needs and ISO 14644 standards.

Pressurization Needs: Select AHUs with advanced pressure control systems to maintain positive or negative pressure as needed for infection control.

Redundancy and Reliability: Consider dual-fan setups and backup components for uninterrupted operation in mission-critical healthcare areas.

Energy Efficiency: Opt for units equipped with VFDs, high-efficiency motors, and heat recovery systems to reduce operating costs.

Compliance Certifications: Verify adherence to ASHRAE 170, EN 1886, ISO standards, and GCC-specific health authority regulations.

Customization Options: ACS CLIMACS Hygienic AHUs offer modular designs that can be tailored to fit unique hospital requirements in the GCC climate.

Supplier Expertise: Work with experienced suppliers like Klima Global that specialize in hospital HVAC systems and provide ongoing technical support.

Proper selection of a Hygienic AHU ensures long-term reliability, reduced infection risks, and compliance with regional and international healthcare standards.

Maintenance and Lifecycle Management

Ensuring the long-term performance of a Hygienic AHU in hospital environments requires a robust maintenance strategy and lifecycle management plan. Preventive care not only sustains air quality but also prolongs the system’s efficiency and reliability.

Key considerations include:

Routine Inspections: Conduct daily and weekly checks of filters, coils, drain pans, and pressure sensors to detect early signs of wear or contamination.

Filter Maintenance: Replace pre-filters and HEPA filters regularly based on pressure drop readings and hospital infection control protocols.

Coil Cleaning and UV-C Lamp Checks: Regularly clean cooling coils and verify UV-C lamps for effective coil sterilization and pathogen control.

Calibration of Sensors: Ensure airflow sensors, temperature probes, and pressure gauges are calibrated quarterly for accurate readings.

Annual Validation: Perform annual airflow validation and leakage tests to comply with ISO 14644 and ASHRAE 170 healthcare ventilation standards.

Predictive Maintenance: Utilize IoT sensors and Building Management System (BMS) data analytics to predict component wear and schedule maintenance proactively.

Lifecycle Planning: Develop a long-term replacement and upgrade plan for components such as fans, motors, and control panels to maintain system efficiency.

Klima Global provides hospitals with specialized maintenance support and a free downloadable AHU Maintenance Checklist Hospital to streamline preventive maintenance routines.

A well-maintained Hygienic AHU ensures reliable operation, consistent indoor air quality, and compliance with GCC health regulations, ultimately safeguarding patient health and reducing total cost of ownership.

Ensure long-term reliability and hygiene of your hospital’s AHUs with our free Preventive Maintenance Checklist for Hospital AHUs, designed for GCC healthcare facilities.

Download Free ChecklistACS CLIMACS Hygienic AHUs – Proven Solutions for GCC Hospitals

Klima Global, through its ACS CLIMACS product line, offers advanced Hygienic AHUs tailored specifically for hospitals and healthcare facilities in the GCC. These solutions are designed to meet stringent air quality, infection control, and energy efficiency standards demanded by modern healthcare environments.

Key benefits of ACS CLIMACS Hygienic AHUs include:

Certified Hygienic Design: Compliance with Eurovent and TUV certifications, ensuring clean and safe construction.

Modular Configurations: Flexible layouts to fit unique hospital requirements, from small clinics to large medical complexes.

Integrated HEPA Filtration and UV-C Technology: Providing multi-layer protection against airborne contaminants.

Advanced Pressure Control: Supporting positive and negative pressure requirements for operating rooms and isolation wards.

Energy Optimization Features: Equipped with VFDs, energy recovery systems, and high-efficiency motors for sustainable hospital operations.

Proven Track Record: Installed successfully in multiple hospitals across UAE, Saudi Arabia, Qatar, and Oman with documented improvements in IAQ and energy savings.

Choosing ACS CLIMACS means investing in a reliable, efficient, and regulation-compliant Hygienic AHU solution backed by Klima Global’s expertise and regional service network.

Looking to enhance your hospital’s air quality? Explore our advanced Hygienic AHUs for Hospitals designed specifically for GCC healthcare facilities.

Explore the Hygienic AHU Product PageSummary

Hygienic AHUs are indispensable for ensuring safe and clean indoor air quality in GCC hospitals. By integrating advanced filtration, UV-C sterilization, pressure control, and sustainable design, these specialized units help protect patients and healthcare staff while meeting strict international and regional standards.

From infection control to energy efficiency, every aspect of a Hygienic AHU contributes to improving hospital environmental safety. With proper selection, maintenance, and lifecycle management, hospitals can ensure long-term compliance and reliability.

Klima Global, through its ACS Klima’s CLIMACS solutions, remains committed to delivering certified, efficient, and hygienic air handling units tailored to the needs of modern healthcare facilities across the GCC.

Discover comprehensive Healthcare HVAC Solutions tailored for medical facilities across the GCC, ensuring compliance, energy efficiency, and patient safety.

Explore Healthcare SolutionsFrequently Asked Questions (FAQ)

What is a Hygienic AHU and how does it differ from a standard AHU?

A Hygienic AHU is specifically designed for sterile environments like hospitals. It includes advanced filtration, antimicrobial surfaces, and UV-C sterilization, unlike standard AHUs meant for commercial spaces.

Which hospital areas in GCC facilities require Hygienic AHUs the most?

Critical areas such as operating rooms, ICUs, NICUs, isolation wards, and clean laboratories require Hygienic AHUs for controlled airflow and infection prevention.

What international standards apply to Hygienic AHUs in healthcare environments?

Standards include ASHRAE 170 for healthcare ventilation, ISO 14644 for cleanrooms, HTM 03-01 for hygienic HVAC design, and GCC Ministry of Health regulations.

How often should filters in a Hygienic AHU be replaced?

Pre-filters are typically replaced monthly, while HEPA filters should be replaced every 6–12 months based on usage and pressure drop readings.

Can FAHUs be used instead of Hygienic AHUs in hospitals?

No, FAHUs (Fresh Air Handling Units) lack the specialized hygienic design, filtration, and sterilization features required for hospital applications.

What role do UV-C lamps play in Hygienic AHUs for infection control?

UV-C lamps disinfect coils and neutralize airborne pathogens within the AHU, preventing microbial buildup and enhancing infection control.

How do Hygienic AHUs help maintain negative and positive room pressures?

Integrated airflow and pressure sensors enable Hygienic AHUs to maintain precise positive pressure in clean areas and negative pressure in isolation rooms.

Are Hygienic AHUs energy-efficient in GCC’s harsh climate?

Yes, modern Hygienic AHUs include VFDs, energy recovery wheels, and high-efficiency motors to handle GCC’s demanding climate while saving energy.

What maintenance tasks are essential for the long-term reliability of Hygienic AHUs?

Regular filter replacement, coil cleaning, UV-C lamp checks, airflow calibration, and annual system validation ensure long-term reliability.

Why choose ACS CLIMACS Hygienic AHUs from Klima Global for GCC hospitals?

ACS CLIMACS units are certified, regionally optimized, and proven in multiple GCC hospitals, offering advanced hygiene, reliability, and energy efficiency.

Share this post

Related Posts

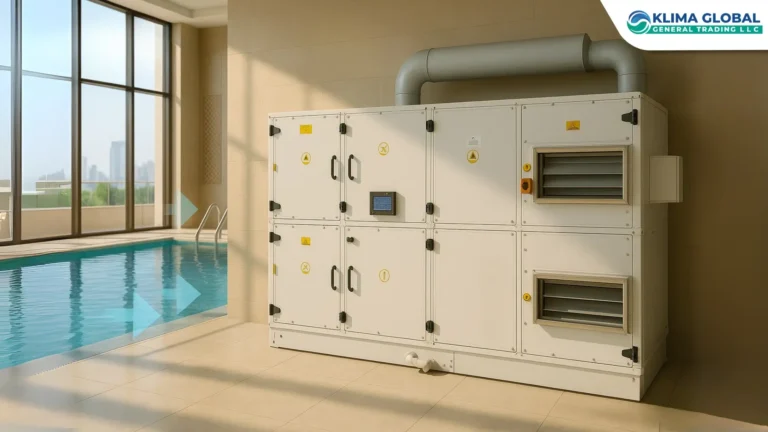

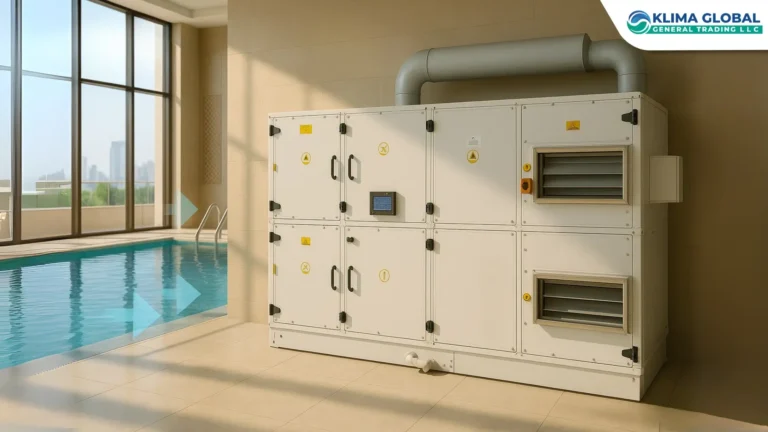

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global

Latest Posts

Fresh Air Handling Units: Components, Operation & Maintenance

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global