Industrial Air Curtains: Enhancing Efficiency and Protection for GCC Warehouses

Warehouses and industrial facilities across the GCC—including the UAE, Saudi Arabia, Qatar, Oman, Bahrain, and Kuwait—face unique operational challenges. From extreme heat to humidity and dust, large entryways in logistics hubs and factories become gateways for energy loss, contamination, and worker discomfort. Every time a loading dock door opens, valuable cooled air escapes, straining HVAC systems and threatening product quality.

The solution is the Industrial Air Curtain—a powerful system designed to shield large doorways, reduce energy waste, and maintain safer, more comfortable environments in warehouses across the GCC and the wider Middle East.

The Challenges of Warehouses in GCC

Energy Loss: Massive doors in warehouses allow conditioned air to escape, increasing HVAC costs.

Dust & Sandstorms: Common across Saudi Arabia, UAE, Qatar, and Oman, introducing contamination risks.

Worker Comfort: Extreme heat in GCC climates causes unsafe and uncomfortable working conditions.

Product Safety: Perishables, pharmaceuticals, and sensitive goods in Bahrain, Kuwait, and other markets suffer from temperature fluctuations.

These challenges directly impact operational costs, safety, and compliance for industrial operators across GCC countries.

What is an Industrial Air Curtain?

An Industrial Air Curtain is a heavy-duty device installed above large entryways, producing a high-velocity stream of air that forms an invisible barrier. Unlike retail or office air curtains, industrial models are designed for openings up to 6–8 meters in height and width.

How they work: Centrifugal fans generate strong airflow across the doorway, separating indoor and outdoor environments.

Applications: Warehouses, cold storage facilities, food industry distribution centers, and manufacturing plants.

Difference from standard air curtains: Greater airflow velocity, durable construction, and enhanced protection for high-traffic environments in UAE, Saudi Arabia, Qatar, Oman, Bahrain, and Kuwait.

Key Benefits of Industrial Air Curtains for Warehouses

Energy Savings: Reduce cooling and refrigeration loads by up to 30–40% across GCC.

Worker Comfort & Safety: Maintain stable indoor environments for staff in extreme heat.

Hygiene & Protection: Prevent dust, insects, and fumes from entering warehouses in desert climates.

Product Integrity: Essential for perishable foods, pharmaceuticals, and sensitive materials throughout GCC warehouses.

Applications Across GCC Industries

Logistics & Distribution Centers: Heavy truck traffic in Dubai, Riyadh, and Doha causes frequent air exchange; air curtains minimize losses.

Cold Storage Warehouses: Maintain temperature stability and energy efficiency (see [Cold Storage Air Curtain Article]).

Manufacturing Plants: Protect machinery in Oman and Bahrain from dust and humidity.

Food Industry Warehouses: Ensure hygiene and compliance with GCC and international standards in Saudi Arabia, UAE, and Kuwait.

From Jebel Ali Free Zone in Dubai to King Abdullah Port in Saudi Arabia, and major hubs in Qatar, Oman, Bahrain, and Kuwait, Industrial Air Curtains play a vital role in regional operations.

Technical Selection Guide

Choosing the right Industrial Air Curtain depends on:

Door Height & Width: Determines whether centrifugal heavy-duty models are required.

Airflow Velocity & Volume: Must match the facility’s environment and pressure conditions.

Mounting Options: Surface-mounted, recessed, or suspended based on facility design.

Noise & Maintenance: Industrial units balance performance with operational ease.

👉 For detailed technical criteria, see our [Air Curtain Technical Selection Guide].

ROI & Energy Efficiency

High ROI: Typical payback within 12–24 months across GCC due to reduced HVAC and refrigeration costs.

Operational Savings: Lower maintenance compared to physical vestibules or plastic strip curtains.

Backlinked Content: Supported by [ROI-Focused Air Curtain Article] and [Energy-Saving Air Curtains Article].

In facilities operating 24/7 in Saudi Arabia, UAE, Qatar, Oman, Bahrain, and Kuwait, ROI is achieved faster, making Industrial Air Curtains a strategic investment.

Sustainability & Compliance

Industrial Air Curtains contribute to regional energy efficiency mandates:

UAE: Support DEWA and Estidama energy codes.

Saudi Arabia: Align with Vision 2030’s sustainability goals.

Qatar: Complement National Vision 2030 for sustainable infrastructure.

Oman & Bahrain: Improve operational efficiency and support regional green initiatives.

Kuwait: Enhance energy performance in industrial hubs.

Certifications: Contribute to LEED, ISO, and food safety compliance across the GCC.

By reducing HVAC demand and cutting emissions, air curtains help industries across all GCC countries align with both cost-saving and sustainability agendas.

Why Choose Klima Global for Industrial Air Curtains

Specialized Solutions: Heavy-duty centrifugal Industrial Air Curtains engineered for GCC conditions.

Regional Expertise: Serving UAE, Saudi Arabia, Qatar, Oman, Bahrain, Kuwait, and the wider Middle East.

Comprehensive Support: From selection to after-sales service, ensuring long-term performance.

Trusted Projects: Proven deployments in warehouses, cold storage, and logistics hubs across GCC.

Klima Global is the partner of choice for businesses seeking efficiency and compliance across all GCC markets.

Conclusion

For warehouses and industrial facilities across the GCC—including UAE, Saudi Arabia, Qatar, Oman, Bahrain, and Kuwait—the Industrial Air Curtain is more than a barrier—it’s a tool for energy efficiency, worker safety, and product protection. Whether at logistics hubs in Dubai, food warehouses in Riyadh, industrial plants in Doha, or distribution centers in Manama, Industrial Air Curtains deliver measurable benefits and fast ROI.

Looking for Industrial Air Curtain solutions in UAE, Saudi Arabia, Qatar, Oman, Bahrain, Kuwait, or the wider Middle East? Contact Klima Global today for expert guidance and tailored solutions.

FAQs: Industrial Air Curtain

Which air curtain type and size are best for warehouse and factory doors in the GCC?

For large roller shutters, dock doors, and wind-exposed openings, specify high-pressure centrifugal air curtains. Match unit width to clear door width (avoid gaps), and select by mounting height and target threshold velocity:

Mounting height: centrifugal units typically cover ~3.5–5.5 m (confirm per model datasheet).

Threshold velocity at the sill: ~2.5–3.0 m/s for most industrial doors; ≥3.0 m/s where wind or negative pressure is high.

Vertical mounting: for very wide doors or constrained headers, consider vertical pairs (left/right jambs) to maintain a coherent jet.

How do we maintain performance under wind, negative building pressure, or constant forklift traffic?

Pressure & wind: size for higher outlet velocity and tune nozzle angle (0–10° outward) on site; use centrifugal units for extra pressure capability.

Controls: interlock to door/roller-shutter limit switches so the unit ramps to high speed only when the door is open; use standby/low speed otherwise.

Pre-start & run-on: add a short pre-start before door fully opens and a run-on delay after it closes to stabilize the barrier.

Vertical pairs: on extreme spans, vertical jamb-mount units keep the jet intact across the width.

What should we specify for cold rooms, chilled docks, and temperature segregation?

Choose cold-room-rated or high-pressure centrifugal air curtains with setpoints to hold the sill line, reduce warm/moist air ingress, and help limit condensation/icing. Typical targets:

Cold storage doors: ≥2.5–3.0 m/s at the sill; confirm with your process and food-safety requirements.

Controls: door-open interlocks, run-on timers, and seasonal nozzle re-tuning as ambient conditions change.

Where vestibules or dock shelters exist, coordinate the air curtain placement to avoid recirculation.

What control and BMS strategy gives the best ROI on industrial doors?

Door interlock: tie the air curtain to shutter/photo-eye/limit switches for automatic high speed only when the door is open.

VFD/EC speed staging: set low/standby, normal, and boost profiles for traffic peaks and windy periods.

BMS integration: provide run/stop, speed/setpoint, and fault points; align time-of-day schedules with shift patterns to minimize kWh.

Diagnostics: log threshold velocity and dB(A) at commissioning; trend in BMS to catch performance drift.

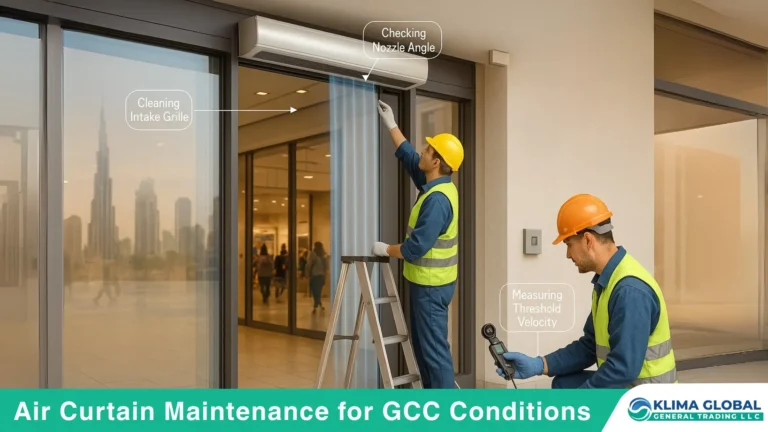

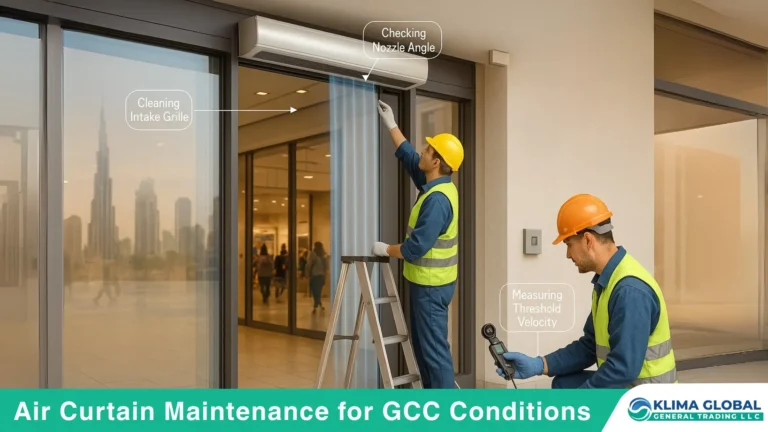

How do we ensure durability and low noise in dusty, saline, or corrosive GCC environments?

Materials & finish: consider powder-coated or stainless-steel housings; specify appropriate IP/ingress protection for the location.

Clear intake: keep bulkheads/signage away from the grille; a starved intake causes hiss/tonal noise and performance loss.

Maintenance plan: monthly grille/fan-wheel cleaning and fastener checks; quarterly sill velocity & dB(A) readings with nozzle re-tune; annual bearing/balance inspection and BMS point verification.

Spares: include filters/grilles, bearings, door sensors, and fan wheels in the BOQ to cut downtime.

Get Customized Air Curtains for your Project!

Share this post

Related Posts

Best Air Curtain Supplier in Saudi Arabia | Buyer’s Guide

Low Noise Air Curtain | Silent Air Curtains for Hotels & Offices

The Ultimate Guide to Air Curtains in the Middle East

Air Curtain Maintenance Guide –Checklist, Service & Lifespan

Air Curtain Installation Guide – Mounting, Sensors & BMS

Latest Posts

Best Air Curtain Supplier UAE | 2025 Buyer’s Guide

Best Air Curtain Supplier in Saudi Arabia | Buyer’s Guide

Low Noise Air Curtain | Silent Air Curtains for Hotels & Offices

The Ultimate Guide to Air Curtains in the Middle East

Air Curtain Maintenance Guide –Checklist, Service & Lifespan

Air Curtain Installation Guide – Mounting, Sensors & BMS