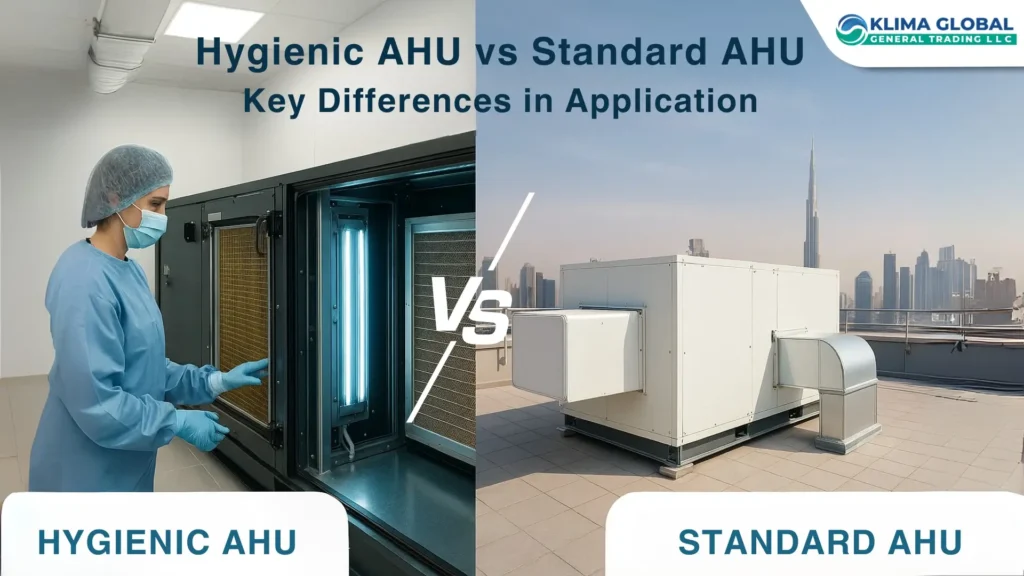

Hygienic AHU vs Standard: Choosing the Right Unit for GCC Projects

In the GCC’s challenging climate—characterized by high heat, humidity, and airborne dust—selecting the right air handling unit (AHU) is critical. The decision between a hygienic AHU vs standard AHU affects indoor air quality (IAQ), regulatory compliance, operational efficiency, and lifecycle costs. For sectors like healthcare, pharmaceuticals, and food processing, the stakes are high. In commercial spaces, performance and cost-effectiveness often take priority. This article, based on Klima Global’s extensive GCC experience with CLIMACS AHUs, provides a detailed, SEO-optimized comparison to guide engineers, consultants, and facility managers.

If you are looking for a broader overview of air handling solutions in the region, read our Air Handling Units UAE – Complete Guide to understand the basics before diving deeper.

What is a Hygienic AHU?

A hygienic AHU is specifically designed for environments that require stringent IAQ control and compliance with standards such as DIN 1946-4 and VDI 6022.

Key Features:

TB1 thermal break, double-skin casing for insulation and hygiene

Smooth, cleanable internal surfaces to prevent microbial growth

Sloped stainless steel drain pans for efficient condensate removal

Multi-stage filtration: pre-filters, fine filters, and HEPA filters for particle removal down to 0.3 microns

UV-C sterilization and antimicrobial coatings to neutralize pathogens

Applications: Hospitals, operating theatres, pharmaceutical cleanrooms, laboratories, and food production facilities.

For healthcare-specific design insights, explore our Pharmaceutical vs Hospital HVAC Standards to see how hygienic AHUs fit into critical environments.

What is a Standard AHU?

A standard AHU delivers conditioned air for comfort cooling and general ventilation, without the specialized hygiene-focused design of a hygienic unit.

Key Features:

Insulated casing for thermal performance

Filtration with pre-filters and fine filters for general IAQ

Galvanized or coated steel drain pans

Flexible configurations for various commercial applications

Applications: Offices, malls, hotels, schools, and mixed-use developments.

If you want to understand where a standard AHU sits among other types, see our FAHU vs AHU – Key Differences for a full comparison.

Key Design Differences

| Feature | Hygienic AHU | Standard AHU |

|---|---|---|

| Casing | TB1 double-skin, antimicrobial finish | Standard insulated casing |

| Filtration | Pre, fine, HEPA (H13 or higher) | Pre and fine filters only |

| Drainage | Sloped stainless steel pans | Galvanized/coated steel pans |

| Finish | Antimicrobial coatings | Standard powder coating |

| IAQ Enhancements | UV-C, antimicrobial linings | Optional upgrades |

| Compliance | Meets DIN, VDI, GMP, ISO | Meets comfort cooling standards |

Regulatory & Compliance in GCC

UAE: Dubai Health Authority (DHA), Ministry of Health (MOH)

Saudi Arabia: Saudi Food and Drug Authority (SFDA)

Pharma: Good Manufacturing Practice (GMP), ISO 14644

General IAQ: ASHRAE 62.1

For detailed guidance on energy-efficient, compliant systems, read our Energy Efficient AHU GCC article.

Maintenance & Lifecycle

Hygienic AHUs:

Frequent HEPA replacement for optimal filtration

Scheduled coil cleaning, casing disinfection, and UV-C lamp checks

Compliance audits and documentation

Standard AHUs:

Lower maintenance intensity

Less frequent filter replacement

Standard coil cleaning schedules

To see exactly what maintenance entails, refer to our AHU Maintenance Checklist UAE for step-by-step servicing tasks.

Hygienic AHU vs Standard: Cost vs ROI Analysis

Hygienic AHUs:

Higher capital expenditure

Essential for critical environments; mitigates risks of IAQ-related downtime or contamination

Long-term savings through compliance and reduced infection rates

Standard AHUs:

Lower upfront investment

Faster ROI in commercial environments without stringent IAQ requirements

You can compare more lifecycle factors in our How to Select the Right AHU resource.

When to Choose Hygienic vs Standard

Hygienic AHU: Select for healthcare, pharma, cleanrooms, and high-IAQ projects

Standard AHU: Suitable for offices, malls, hospitality, and general comfort cooling

Common Misconceptions About Hygienic AHU vs Standard

Myth: Hygienic AHUs are only for hospitals – Fact: They’re also ideal for food production and luxury hospitality.

Myth: Standard AHUs cannot achieve high IAQ – Fact: Upgrades can significantly enhance IAQ.

Myth: Hygienic AHUs are less energy efficient – Fact: Modern designs integrate EC fans and energy recovery systems.

Klima Global Advantage

Klima Global delivers both hygienic AHUs and standard CLIMACS AHUs engineered for GCC conditions. Our designs incorporate TB1 thermal break construction, marine-grade coatings, advanced filtration, and energy-efficient fans for maximum performance.

If your project demands proven, regional expertise, contact us or review our GCC Hospital AHU Case Study to see how we deliver results.

FAQ – Hygienic AHU vs Standard

What’s the difference between hygienic and standard AHUs?

Hygienic AHUs are purpose-built for environments where air cleanliness is critical, using multi-stage filtration (including HEPA), antimicrobial finishes, and easily cleanable components. Standard AHUs focus on delivering comfort cooling with general filtration and standard finishes, making them more cost-effective for non-critical applications.

Can a standard AHU meet healthcare standards?

Yes, but only with significant upgrades such as the addition of HEPA filters, antimicrobial coatings, and enhanced condensate drainage. Even with these upgrades, it’s important to validate performance against healthcare regulations before deployment.

Are hygienic AHUs more expensive to operate?

They have higher operational costs due to frequent filter replacements, coil cleaning, and compliance inspections. However, these costs are often offset by reduced contamination risks, improved patient safety in healthcare, and prevention of costly downtime in critical facilities.

What regulations apply in GCC?

Regulations vary by country and sector but include DHA and MOH standards in the UAE, SFDA in Saudi Arabia, GMP and ISO 14644 for pharmaceuticals, and ASHRAE 62.1 for IAQ. Hygienic AHUs are typically designed to meet or exceed these requirements without modification.

Can hygienic AHUs be energy efficient?

Yes, when equipped with EC motors, energy recovery systems, and optimized airflow controls, hygienic AHUs can achieve high energy efficiency while still meeting strict IAQ and compliance standards.

Get Customized HAHU Unit for your Project

Share this post

Related Posts

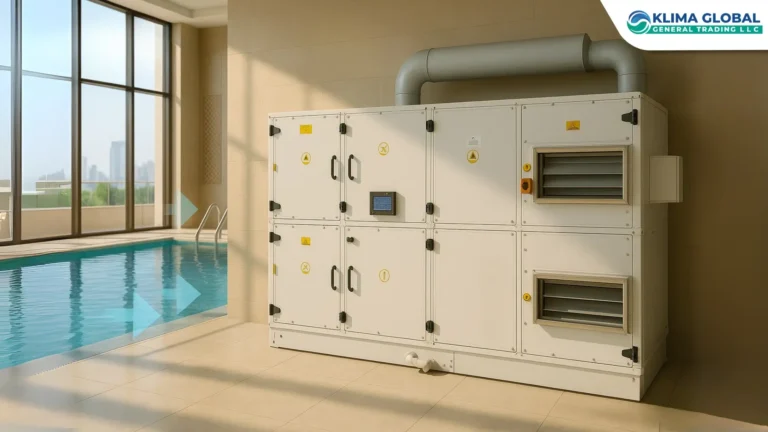

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global

Latest Posts

Fresh Air Handling Units: Components, Operation & Maintenance

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global