Why AHU Maintenance Matters in the UAE?

Effective AHU maintenance is essential for building operations in the UAE, where extreme heat, dust, and humidity can quickly affect HVAC system performance if not regularly addressed.

In the harsh and dusty climate of the UAE, maintaining an Air Handling Unit (AHU) isn’t just good practice—it’s a necessity. From Dubai’s coastal humidity to Abu Dhabi’s desert winds, environmental extremes can significantly degrade HVAC performance if regular upkeep is overlooked.

AHU maintenance in the UAE ensures that air quality stays high, energy bills stay low, and systems remain compliant with regional sustainability codes like DEWA and Estidama. Poorly maintained AHUs can lead to airflow inefficiencies, occupant discomfort, filter blockages, corrosion, and even equipment failure.

This article provides a practical, UAE-specific checklist to help engineers, facility managers, and MEP contractors keep AHUs running reliably throughout the year. Let’s dive into the preventive tasks and expert insights that will extend the life and performance of your HVAC system in the region’s toughest environments.

To understand the fundamentals of system design and airflow control, explore our Air Handling Units in the UAE: Complete Guide—an in-depth breakdown of types, selection criteria, and applications.

Safety Precautions Before Starting Maintenance

Before performing any AHU maintenance, it’s critical to follow safety protocols that protect both personnel and equipment. The UAE’s rooftop installations and high ambient temperatures further increase operational risks, especially during summer months. Here are essential steps to take:

Power Isolation and Lockout/Tagout

Always disconnect the unit from the electrical supply before opening any access panel. Use lockout/tagout procedures to ensure no accidental restart occurs during inspection or servicing. This protects technicians from electrical hazards and rotating fan components.

Access Panel Handling and Inspection

Use appropriate tools and PPE when removing or securing access panels. Check for pressurization before opening and ensure panels are stored securely to prevent damage or injury. Inspect panel gaskets and hinges for wear and tear—especially in coastal or dusty conditions.

Working at Heights (for Rooftop AHUs)

Many AHUs in UAE buildings are installed on rooftops. Always use certified fall protection gear and follow OSHA or local safety standards for working at heights. Inspect the rooftop surface for trip hazards, loose grating, or pooling condensate.

Adhering to these precautions minimizes risk and ensures technicians can safely conduct routine and corrective maintenance without incident.

Monthly & Quarterly AHU Maintenance Tasks

A proactive schedule of monthly and quarterly checks is the cornerstone of effective AHU maintenance in the UAE. Here’s a practical service checklist based on manufacturer recommendations and Klima Global’s regional expertise:

Filter Cleaning or Replacement Schedule

Frequency: Check filters monthly; replace every 1–3 months depending on dust exposure.

Recommended Type: MERV 13 or HEPA filters for maximum air purification.

Signs of Trouble: Reduced airflow, increased energy use, or dirty return grilles.

Coil Cleaning and Inspection

Cooling Coils: Inspect quarterly for dust, biological growth, or corrosion.

Drain Pans: Ensure proper slope, clear blockages, and sanitize to prevent microbial growth.

Cleaning Tip: Use non-corrosive coil cleaners approved for aluminum or copper coils.

Fan and Motor Lubrication

Inspect fan blades for dirt or imbalance.

Lubricate bearings as per manufacturer interval (typically quarterly).

Check for unusual vibration or sound during operation.

Electrical Connection and Safety Sensor Check

Tighten all terminal screws and inspect for burn marks or wear.

Test airflow switches, differential pressure sensors, and emergency shut-offs.

Ensure control panels are sealed and dust-proof to prevent failure.

Following this checklist not only preserves airflow and cooling efficiency but also helps facilities avoid unscheduled downtime in peak seasons. Coming up next: the common issues that these maintenance routines are designed to prevent.

Looking for help with AHU specification and sizing? See our guide on How to Select the Right AHU to simplify your decision-making process.

Common AHU Problems in UAE Conditions

Even with regular servicing, AHUs in the UAE face unique environmental challenges that can lead to performance issues if not monitored carefully. Here are some of the most common problems seen in the region:

Condensation and Corrosion in TB1 Panels

Excess humidity and temperature variations can result in internal condensation, particularly in non-TB1-class units. Over time, this leads to microbial growth, rust, and structural degradation. Ensure your AHU is built with TB1 thermal bridging class materials to reduce this risk.

Airflow Drop from Dust Buildup

UAE’s frequent sandstorms and high dust index contribute to filter clogging and coil fouling. This restricts airflow, strains fan motors, and reduces cooling efficiency. Continuous monitoring and frequent filter replacement are critical to avoid pressure drops.

Motor Overheating Due to Load and Climate Stress

High ambient temperatures and clogged filters cause motors to work harder than necessary, often leading to overheating or burnout. Lack of proper lubrication or misaligned belts can worsen the situation. Motor vibration checks and thermal overload protection should be part of regular inspections.

Understanding these issues can help facility managers preempt failures, improve lifecycle performance, and avoid emergency shutdowns—especially during high-demand months.

Fresh air dilution and hygiene are critical in GCC environments. Read Fresh Air Handling Units in the UAE to learn how FAHUs combat dust and improve IAQ.

Preventive Maintenance Best Practices

To maximize uptime and operational efficiency, AHU systems in the UAE require a preventive maintenance approach tailored to local climate and usage patterns. Here’s how to stay ahead:

Use of TB1 Insulated Panels

Ensure your AHU is constructed using TB1-rated panels to eliminate thermal bridges. This prevents surface condensation and corrosion, especially in high-humidity or coastal applications. Regularly inspect panel joints, insulation integrity, and condensation trays.

Implementing Smart Controls & Sensors

Modern AHUs should include integrated sensors that track pressure differential, humidity, temperature, and motor current draw. Connect these to a Building Management System (BMS) or standalone smart controller to enable:

Predictive maintenance alerts

Filter clogging alarms

Real-time performance diagnostics

Routine Airflow Balancing

Seasonal changes, tenant occupancy, and filter load can disrupt airflow distribution. Use anemometers to test supply and return flows quarterly. Adjust dampers, fan speed (if VFD-equipped), and re-balance zones to maintain target air volume and pressure.

By following these best practices, AHU systems stay aligned with both performance targets and GCC compliance expectations, reducing maintenance surprises and boosting HVAC ROI.

Concerned about condensation and corrosion? Learn why TB1 construction matters in our article Prevent AHU Condensation and Corrosion: The Importance of TB1, especially in humid and coastal GCC environments.

Post-Maintenance Startup Inspection

Once maintenance is completed and systems are re-energized, it’s essential to perform a structured post-startup inspection to confirm safe, stable operation:

Fan and Motor Vibration Check

Power up the unit and listen for unusual vibration or imbalance.

Use a vibration analyzer to confirm readings are within manufacturer specs.

Check that fan blades rotate smoothly and motors are not overheating.

Airflow Monitoring and Calibration

Measure airflow output at supply and return points.

Compare actual airflow against design values and adjust VFDs or dampers if necessary.

Confirm that sensors are reading and reporting accurately within your BMS.

Belt Alignment and Tension Test

Inspect pulley alignment and belt tension.

Re-tension or replace worn belts to avoid squeal or slippage.

Confirm belt guards are in place before closing the unit.

Completing this checklist ensures your AHU returns to optimal operating condition, minimizing the risk of early faults and ensuring indoor air quality is not compromised following service.

Maintenance Tips Specific to Klima Global AHUs

Klima Global’s AHU systems, powered by ACS Klima engineering, are built for durability and high performance in the GCC region. However, proper maintenance is key to unlocking their full potential and longevity. Here’s how to care for them correctly:

TB1-Class Panel Cleaning

ACS Klima AHUs use TB1-rated panels to prevent thermal bridging and condensation.

Inspect panel integrity and insulation joints every quarter.

Wipe down internal surfaces with a non-corrosive cleaner to prevent microbial build-up.

ACS Klima Access Door System Checks

Doors are equipped with heavy-duty hinges and gaskets. Check that gaskets are intact and seated properly.

Ensure pressure-tight handles close fully to avoid air leakage.

Lubricate hinges and inspect for metal fatigue or corrosion on access frame.

Integrated Control Panel Maintenance

Klima’s smart AHUs may feature EC fans, VFDs, and sensor suites.

Verify controller firmware is up to date and responsive.

Check BMS connectivity, especially during sensor recalibration or after power events.

These system-specific practices help maximize the return on investment for Klima Global clients and reduce long-term operating costs in challenging environments.

Want a deeper look at hygienic units? Visit our Hygienic AHUs product page for features and compliance details tailored to hospitals and clean zones.

Klima Global’s Technical Support and AMC Options

Klima Global offers robust after-sales support and maintenance solutions to ensure your AHUs perform efficiently over the long term. Whether you’re managing a commercial tower in Dubai or a healthcare facility in Sharjah, our services are tailored to meet your operational needs.

Annual Maintenance Contracts (AMC)

Scheduled inspections and preventive service throughout the year

Priority response for emergencies and breakdowns

Comprehensive reports for compliance and audits

On-Call Diagnostics and Repair Service

Rapid deployment of skilled technicians within UAE and GCC

Root-cause analysis and corrective actions

Real-time reporting via our service dashboard

Parts Availability and Regional Support

Genuine ACS Klima parts and consumables stocked locally

Faster replacements, minimized downtime

Support across UAE, Oman, KSA, Bahrain, and Qatar

With Klima Global’s technical support, building owners and MEP professionals can focus on operations while we keep air quality and energy efficiency in check—all year round.

Maintenance Checklist for AHU

To streamline your maintenance routine, Klima Global offers a downloadable, branded PDF checklist designed for AHU servicing in UAE conditions. Based on ACS Klima’s official IOM manual, this checklist consolidates all key maintenance tasks.

📥 Download Now: Klima Global AHU Maintenance Checklist (PDF)

What’s Inside:

Klima Global-branded maintenance schedule

Weekly to annual checklists

Special cleaning and inspection steps

Compliance and safety reminders

Print-ready format for facility managers, engineers, and HVAC teams in the GCC

Conclusion

Effective AHU maintenance in the UAE is not a one-time event—it’s a continuous process shaped by climate, operational loads, and technology. With proactive servicing, facilities can ensure optimal air quality, maximize energy savings, and extend equipment lifespan.

Klima Global makes this easy with regionally adapted solutions, expert technical support, and smart preventive tools. Whether you’re running a hotel in Dubai, a hospital in Riyadh, or an office in Muscat, our maintenance guides and services help keep your air handling systems at peak performance.

Need more insight into AHU retrofits, efficiency, or sustainability? Browse our AHU Blog Library for expert tips and GCC-specific maintenance advice.

Need help planning your AHU maintenance program?

Contact our team today for customized Annual Maintenance Contracts, spare parts, or technical support across the GCC.

Visit Klima Global AHU SolutionsShare this post

Related Posts

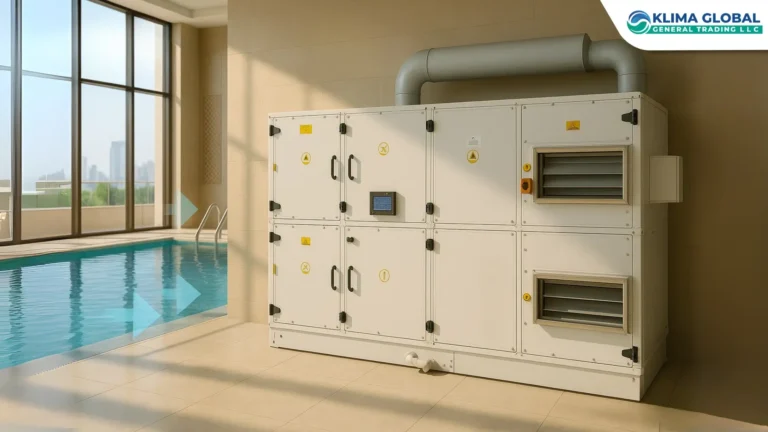

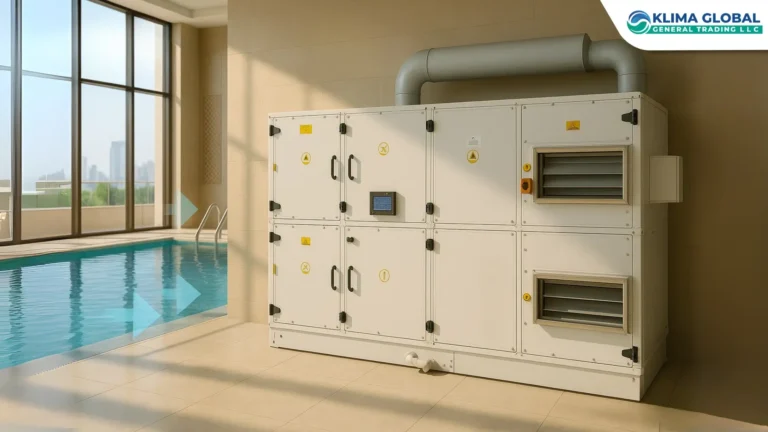

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global

Latest Posts

Fresh Air Handling Units: Components, Operation & Maintenance

Pool Dehumidifier Supplier in UAE & GCC | Package Type

Hygienic Air Handling Unit Supplier in UAE & GCC

Heat Recovery Ventilation Supplier UAE | Klima Global