Air Curtain Maintenance: Checklist for Middle East Conditions

Effective air curtain maintenance is the difference between a quiet, protective air barrier and an underperforming draft. In the harsh climates of the GCC—UAE, Saudi Arabia, Qatar, Oman, Bahrain, and Kuwait—dust, heat, humidity, and coastal corrosion demand a tailored plan. This guide delivers a practical air curtain maintenance checklist for facility managers, MEP contractors, and HVAC service teams, with clear intervals, test methods, and parts planning to maximize performance and lifespan.

For background on system design and setup before service, see our Air Curtain Installation Guide.

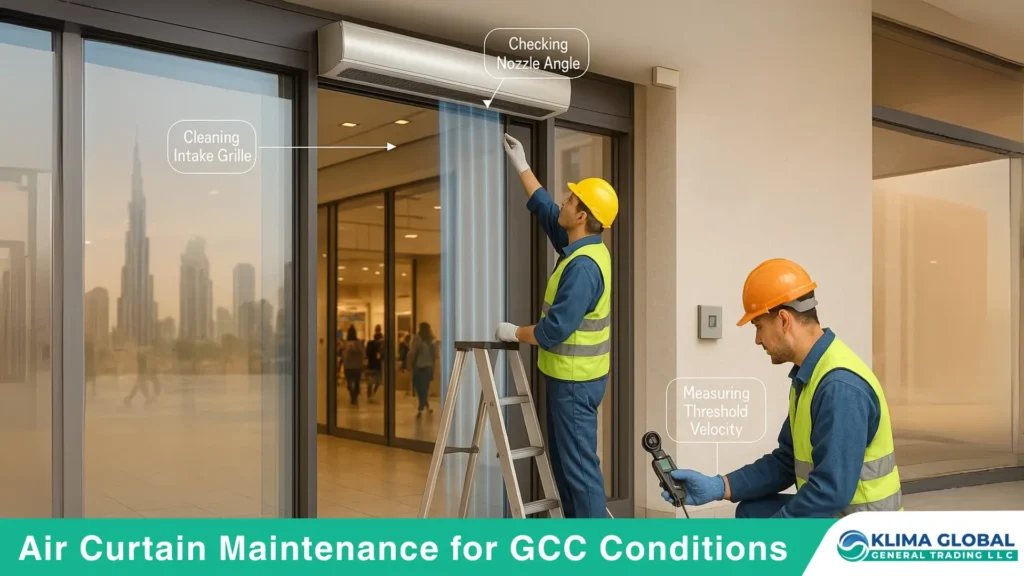

Safety & Tools for Air Curtain Maintenance

Before any air curtain maintenance task, secure the area and isolate power.

Safety: Lockout/Tagout, PPE, fall protection, safe access (lifts/scaffolds).

Tools: Anemometer, sound level meter, vacuum/soft brush, non‑aggressive coil/grille cleaner (for heated units), torque screwdriver, IR thermometer, multimeter, manometer (where applicable).

Docs: Service app/log, baseline photos of nozzle angle, threshold velocity readings, and dB(A) measurements for comparison.

To understand how proper upkeep translates to lower energy bills, explore our Energy Saving Air Curtain article.

Maintenance Philosophy & Intervals

A proactive air curtain maintenance strategy prevents drift in threshold velocity and noise.

Preventive vs reactive: Schedule preventive visits; avoid waiting for complaints or alarms.

Environment‑based intervals: Clean retail (monthly/quarterly), dusty docks (bi‑weekly/monthly), coastal sites (rinse/inspect monthly), kitchens/F&B (more frequent due to grease).

Baseline records: Keep commissioning data—floor velocity, dB(A), nozzle angle, and speed settings—to compare at each visit.

Monthly Air Curtain Maintenance Tasks

Clean intake grilles & filters: Vacuum/brush; replace or wash filters as specified.

Inspect discharge nozzle: Remove debris; confirm continuous, unobstructed outlet.

Visual fastener & casing check: Tighten loose screws; look for corrosion, paint damage, or vibration marks.

Door interlock test: Confirm open/run logic and speed changes.

BMS status review: Verify run/stop, fault, and speed feedback points.

Quarterly Air Curtain Maintenance Tasks

Threshold velocity test: Measure at 3–5 points across the doorway at floor level. Targets: 2.0–2.5 m/s (comfort), 2.5–3.0 m/s (insect/F&B), ≥2.5 m/s (cold rooms).

Nozzle angle tuning: Start at 0–10° outward; adjust to meet targets under real wind/stack conditions.

Noise check: Record dB(A) at a stated distance (e.g., 2 m) and compare to spec.

Internal cleaning: Fan wheels, motor housings, filter frames; check for dust loading that impairs airflow.

Electrical audit: Re‑torque terminals, inspect cables; review EC/VFD parameters and firmware.

Multi‑section alignment: Verify seals between sections and uniform discharge across joints.

Semiannual / Annual Air Curtain Maintenance

Deep clean & bearing inspection: Check balance, play, and wear; lubricate if manufacturer allows.

Motor tests: Insulation resistance and temperature rise per spec.

Heated models: Verify PTC elements or water‑coil integrity; test valves/actuators and high‑limit safety.

Sensor & BMS validation: Recalibrate door sensors; confirm point mapping and alarms; update schedules.

Training & O&M updates: Refresh staff on cleaning frequency; capture as‑found/as‑left readings.

Special Environments Across the GCC

Tailor air curtain maintenance to local conditions.

Coastal (Dubai Marina, Doha Corniche, Bahrain): Rinse casings; use corrosion‑resistant fasteners; inspect for salt deposits and early pitting.

High‑dust / Sandstorms (Saudi, Oman): Increase grille/filter cleaning frequency (weekly during season); stock spare filters.

Kitchens & F&B: Grease‑resistant cleaning; sustain floor velocity 2.5–3.0 m/s for insect control; schedule more frequent wipe‑downs.

Healthcare: IAQ priority; document cleanliness and dB(A); verify stable jet at entrances/pharmacies.

Cold Storage (Qatar logistics): Anti‑frost checks; maintain ≥2.5 m/s at sill; coordinate with door heaters/defrost cycles.

Performance KPIs to Track

Threshold velocity (m/s) vs target bands.

Noise level dB(A) vs specification for FOH/clinical areas.

Energy trend (kWh) pre/post air curtain maintenance.

Entrance comfort & hygiene: customer/occupant complaints, insect ingress reports.

Downtime & fault logs: frequency and root causes.

Trigger corrective actions if KPIs drift—clean filters, adjust angle/speeds, or investigate fan/motor wear.

For sector-specific service demands, such as malls and supermarkets, see our Retail Air Curtains in GCC.

Spare Parts & Consumables Plan

A stocked kit reduces downtime between air curtain maintenance visits.

Filters/grilles, EC/VFD controllers, fan wheels, bearings, door sensors, gasket/seal kits, fasteners, touch‑up paint.

Recommended BOQ for GCC sites; store spares in dry, cool areas away from salt/humidity.

Troubleshooting Quick Guide

Low floor velocity → clogged filters, incorrect nozzle angle, reduced speed/VFD parameter, intake obstruction.

High noise/vibration → loose mounts, fouled or unbalanced fan, bearing wear.

No start → interlock/wiring fault, breaker/isolator off, BMS command inhibit.

Uneven jet → section misalignment, leaks at joints, nozzle contamination.

Overheat trip (heated units) → blocked intake, failed fan, thermostat/high‑limit fault.

If your unit performance issues stem from design rather than maintenance, our Air Curtain Selection Guide can help confirm whether the correct model was specified.

Conclusion

Planned air curtain maintenance keeps thresholds sealed, entrances comfortable, and HVAC costs down—especially in demanding GCC conditions. By cleaning intakes, verifying threshold velocity, auditing controls/BMS, and scheduling deep inspections, you’ll extend equipment life and protect occupant experience.

For hospitals, hotels, and logistics hubs, scheduled service is critical—learn more in our Hospital Air Curtain, Hotel Air Curtain, and Industrial Air Curtain pages.

Need scheduled air curtain maintenance or emergency service in UAE, Saudi Arabia, Qatar, Oman, Bahrain, or Kuwait? Contact Klima Global for site surveys, service contracts, and OEM‑grade parts support.

Frequently Asked Questions

What dB(A) and air performance should I specify for a hotel lobby so it stays quiet but effective?

For premium lobbies and reception areas, target ≤45–50 dB(A) measured ~2 m from the doorway during typical operation. Pair this with a threshold velocity of ~2.0–2.5 m/s (comfort and hygiene without “draft complaints”). Start with a 0–10° nozzle angle and fine-tune on site to keep the jet coherent at the floor.

See also: Air Curtain Installation Guide • Air Curtain Selection Guide

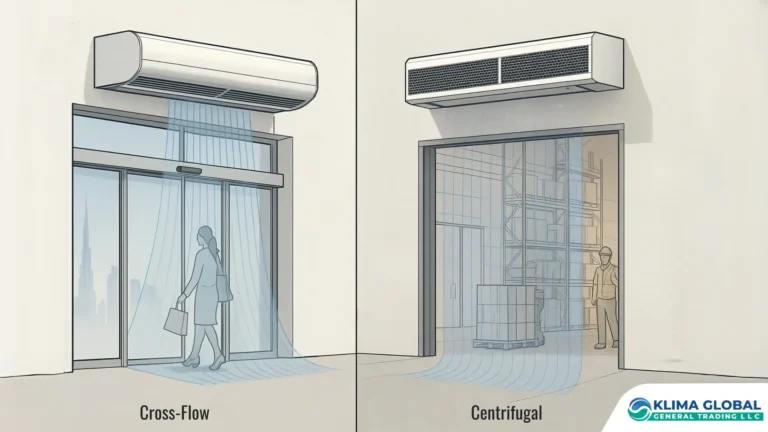

Which models are best for quiet hotel and office entrances in the GCC?

For 2.3–3.0 m mounting heights, low-noise cross-flow units such as Model I and Model K are popular due to their slim profile and quiet fan wheels. For taller vestibules or where higher pressure is needed, choose centrifugal ranges like Model A / A2 / L2 and commission carefully to meet both floor velocity and acoustic targets.

Compare & explore: Air Curtain Comparison • Model I • Model K • Model A • Model A2 • Model L2

How do BMS and door sensors help keep a Low Noise Air Curtain quiet in off-peak hours?

Integrate door interlocks so the unit ramps to high speed only when doors open, and runs at standby speed (or off) otherwise. Add BMS scheduling aligned with access hours, enable run/stop, speed feedback, and fault points, and record a baseline dB(A) after commissioning. This strategy cuts average noise and kWh while preserving entrance comfort.

Implementation links: Air Curtain Installation Guide • Energy Saving Air Curtain

Can I retrofit a noisy entrance to Low Noise Air Curtain performance without replacing the unit?

Often, yes. Start with intake/grille cleaning, fan-wheel cleaning/balancing, tightening fasteners, and realigning the nozzle angle. Add or re-enable door sensors and speed staging. If the unit is undersized (width vs door), under-rated (mounting height), or cosmetically unsuitable for a premium lobby, consider upgrading to a purpose-built Low Noise Air Curtain model.

Quick fixes & criteria: Air Curtain Maintenance Guide • Air Curtain Selection Guide

What should my BOQ/RFP include to guarantee a Low Noise Air Curtain outcome?

Specify a maximum installed dB(A) (with measurement distance and operating mode), design mounting height & door width, required threshold velocity, control logic (door interlock, standby speed, BMS points), and a commissioning report with velocity profile, nozzle angle, and noise readings. Include recommended spare parts and a service plan to sustain acoustic performance.

Ready to specify: Air Blade – Air Curtain • Hotel Air Curtain – GCC

Get Customized Air Curtains for your Project!

Share this post

Related Posts

Best Air Curtain Supplier in Saudi Arabia | Buyer’s Guide

Low Noise Air Curtain | Silent Air Curtains for Hotels & Offices

The Ultimate Guide to Air Curtains in the Middle East

Air Curtain Installation Guide – Mounting, Sensors & BMS

Air Curtain Comparison – Cross-Flow vs Centrifugal

Latest Posts

Best Air Curtain Supplier UAE | 2025 Buyer’s Guide

Best Air Curtain Supplier in Saudi Arabia | Buyer’s Guide

Low Noise Air Curtain | Silent Air Curtains for Hotels & Offices

The Ultimate Guide to Air Curtains in the Middle East

Air Curtain Installation Guide – Mounting, Sensors & BMS

Air Curtain Comparison – Cross-Flow vs Centrifugal