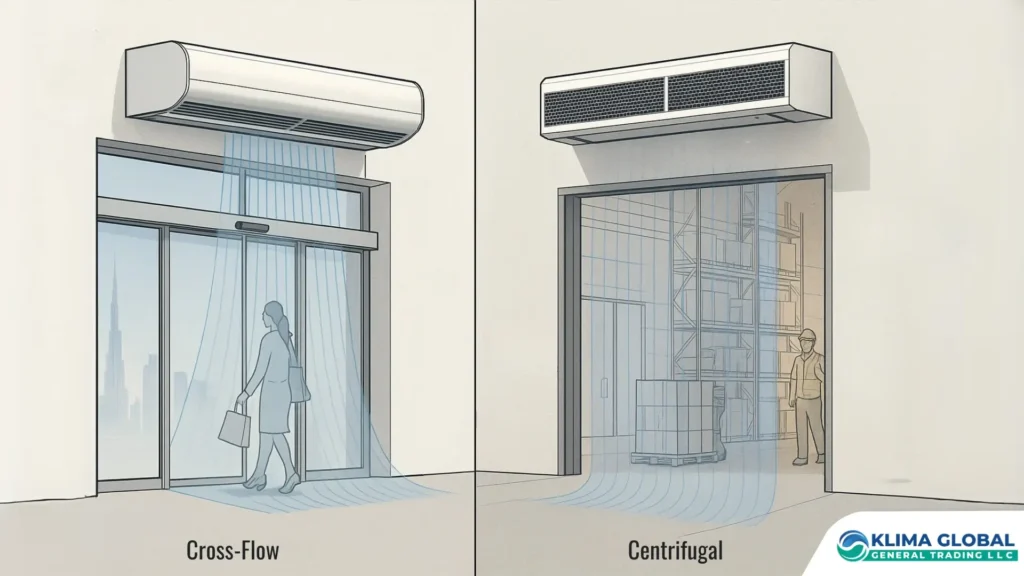

Air Curtain Comparison: Cross-Flow vs Centrifugal for GCC Buildings

This Air curtain Comparison explains, in practical engineering terms, how cross-flow and centrifugal air curtains differ and which technology suits your doorway, mounting height, and use‑case in the GCC—UAE, Saudi Arabia, Qatar, Oman, Bahrain, and Kuwait. If you specify entrances for malls, hotels, hospitals, warehouses, or cold rooms, the right choice affects comfort, hygiene, and energy performance. Use this Air curtain Comparison to match fan type, airflow strength, and acoustic profile to your application—and to avoid under‑sizing that compromises results.

New to the basics? Start with our comprehensive Air Curtains Guide before comparing types.

What Is a Cross-Flow Air Curtain?

A cross‑flow air curtain uses a tangential (cross‑flow) impeller to produce a wide, uniform discharge along the full nozzle length.

Where it excels in the Air curtain Comparison

Slim profile & aesthetics: Ideal where appearance matters—retail storefronts, hotel lobbies, cafés, and reception areas.

Low noise: Typically quieter than industrial units, suiting front‑of‑house spaces.

Typical mounting height: ~2.3–3.5 m above finished floor.

Best use‑cases: Retail & hospitality entrances, healthcare reception corridors, offices.

What Is a Centrifugal Air Curtain?

A centrifugal air curtain uses one or more forward‑curved centrifugal wheels to deliver higher static pressure and velocity.

Where it excels in the Air curtain Comparison

High velocity & throw: Maintains a strong, coherent jet over tall openings.

Overcomes wind/stack effects: Better performance when outdoor winds or pressure differentials oppose the jet.

Typical mounting height: ~4–8 m (large doors and docks).

Best use‑cases: Warehouses, logistics docks, airports, large atria, and cold‑storage portals.

Technical Air Curtain Comparison: Performance Metrics

Static Pressure & Jet Coherence

Centrifugal > Cross‑Flow for static pressure, maintaining jet integrity across tall openings and in windy conditions.

Nozzle Discharge & Floor Velocity

Design bands:

Cross‑flow discharge often 8–14 m/s for doors ≤3.5 m.

Centrifugal discharge commonly 12–18 m/s for 4–8 m mounts.

Floor‑level targets at threshold:

Comfort/energy separation: ~2.0–2.5 m/s.

Insect control (F&B/healthcare): ~2.5–3.0 m/s.

Cold rooms/freezers: ≥2.5 m/s sustained at sill.

Coverage Uniformity & Width

Cross‑flow provides excellent uniformity along width for glass storefronts and lobby doors.

Centrifugal excels where wide spans and tall heights coincide or where cross‑winds exist.

Noise & Acoustics

Cross‑flow units are generally quieter and easier to recess.

Centrifugal units are more powerful; specify acoustic targets (e.g., ≤55–60 dB(A) in FOH/healthcare) and isolation where needed.

Need a step-by-step sizing method after this comparison? Use the Air Curtain Selection Guide and finalize details with the Air Curtain Installation Guide.

Mounting Height & Doorway Types in the Air Curtain Comparison

Cross‑Flow: best up to ~3.5 m; ideal for sliding/swing glass doors; slim casings suit recessed fascias.

Centrifugal: 4–8 m; suits roll‑up/dock doors and wind‑exposed portals; robust frames for industrial settings.

Vertical side‑mount: use only when lintel space is unavailable; ensure continuous coverage across the width.

For lobby heights (≈2.3–3.0 m), shortlist Model I and Model K; for ≥3.5 m or wind-exposed portals, consider Model A, Model A2, or Model L2.

Application Map: Choosing by Sector

Retail & Hospitality (Dubai, Riyadh, Doha): cross‑flow prioritizes quiet operation, aesthetics, and stable comfort with doors open. For storefront specifics (sliding doors, open-front concepts, hypermarkets), see Retail Air Curtain – GCC. For lobby acoustics, porte-cochère winds, and concierge aesthetics, review Hotel Air Curtain – GCC.

Healthcare (UAE & GCC clinics/hospitals): cross‑flow with enhanced filtration to support IAQ and hygiene near lobbies and pharmacies. For patient-facing entrances and coordination with infection-control policies, start with Hospital Air Curtain – GCC.

Industrial & Warehouses (Saudi, Qatar, Oman): centrifugal to reduce energy loss and dust ingress at high loading bays. For tall roller shutters, wind-exposed bays, and vertical jamb mounts, see Industrial Air Curtain – GCC and the pressure-capable Industrial Air Curtain (Centrifugal Type).

Cold Storage (GCC food logistics): centrifugal or dedicated cold‑room air curtains to prevent cold loss, condensation, and ice. For frost/condensation control at chiller/freezer doors, see Cold Storage Air Curtain – GCC and product details at Cold Room Air Curtain.

Quick Air Curtain Comparison

Inputs: door height & width, wind/pressure, traffic intensity, IAQ/hygiene needs, acoustic limits.

Outputs: recommended technology, velocity targets, and control package.

| Parameter | Cross‑Flow | Centrifugal |

|---|---|---|

| Mounting height | ~2.3–3.5 m | ~4–8 m |

| Acoustic profile | Quieter (FOH) | Louder/powerful (BOH) |

| Static pressure | Moderate | High |

| Typical use | Retail, hospitality, healthcare | Warehouses, docks, cold rooms |

| Wind/stack resistance | Moderate | Strong |

Use this Air curtain Comparison to avoid specifying a slim cross‑flow unit on a wind‑exposed dock, or an industrial centrifugal unit in a boutique lobby.

Controls & Integration

Door interlock (open = run), staged speeds or VFD, and BMS integration (dry contact/Modbus).

Seasonal presets for summer/winter; insect control modes for F&B.

Heated options (PTC or water coil) for mixed climates or guest comfort at entrances.

Klima Global Model Map

Leverage this Air curtain Comparison with Klima Global’s range:

Cross‑Flow (Front‑of‑House): Model K / G / O / B / I – slim, quiet, ideal up to ~3.5 m.

Centrifugal/Industrial (Back‑of‑House): Model A / A2 / G2 / L / L2 – high velocity for 4–8 m doors.

Cold Room Series: purpose‑built units for freezers/coolers.

Heated Options: Model E2 (PTC Heating) and Water‑Heating Cross‑Flow.

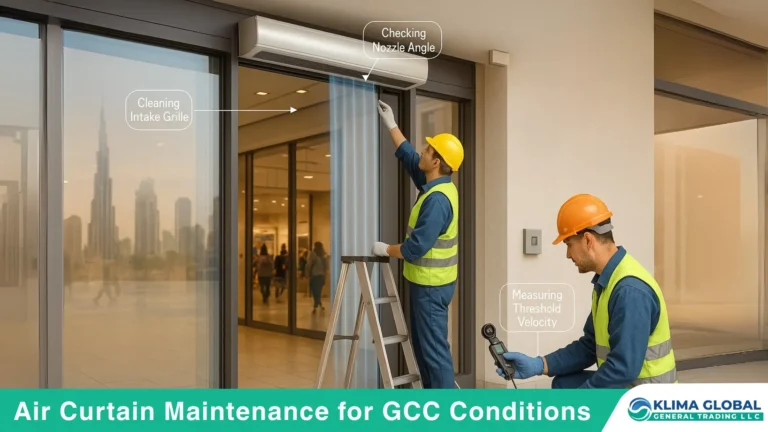

Installation Notes & Best Practices

Correct installation is as important as the technology choice in any Air curtain Comparison:

Full‑width coverage with no gaps; align and seal multi‑section arrays.

Mount tight to lintel, keep intake/discharge unobstructed; start with 0–10° outward tilt.

Commission with anemometer readings at multiple points across the threshold; verify floor velocity targets.

Schedule maintenance for filter cleaning and periodic velocity checks.

See also: Air Curtain Installation Best Practices

Case Snapshots (GCC)

Crossflow Air Curtain Dubai: Luxury storefront, 3.2 m mount, recessed cross‑flow unit meets ≤55 dB(A); floor velocity ~2.3–2.5 m/s with doors open.

Centrifugal Air Curtain GCC: Riyadh logistics dock, 6 m mount; high‑velocity centrifugal unit maintains ≥2.5 m/s at sill despite cross‑winds.

Cold Room – Doha: Centrifugal cold‑room model preventing condensation and keeping sill velocity ≥2.5 m/s during peak loading.

Conclusion

In this Air curtain Comparison, cross‑flow units emerge as the go‑to for quiet, elegant front‑of‑house environments up to ~3.5 m, while centrifugal units dominate high doors, wind‑exposed docks, and cold rooms from ~4–8 m. By aligning technology to height, wind/pressure, and IAQ or hygiene goals, you’ll protect comfort, save energy, and meet GCC sustainability targets.

Ready to specify by height and finish? Browse the full Air Blade – Air Curtain range.

Ready to act on this Air curtain Comparison? Contact Klima Global for help matching models, setting velocity targets, and preparing submittal‑ready specs for UAE, Saudi Arabia, Qatar, Oman, Bahrain, and Kuwait.

FAQs: Air Curtain Comparison

Cross-Flow vs Centrifugal — which type should I choose for my entrance?

Choose Cross-Flow for most hotel and office doors at ~2.3–3.0 m mounting height where you want slim aesthetics and low noise (e.g., lobbies, reception foyers). Choose Centrifugal for >3.5 m mounts, wind-exposed doors, or wider spans where higher pressure is needed to hold threshold velocity at the floor. Always match unit width to door width, verify nozzle angle (0–10°) on site, and confirm floor velocity with an anemometer.

Which option is quieter for premium hotel lobbies and boardroom floors?

At typical lobby heights, Cross-Flow units are generally the quieter choice thanks to their fan geometry and slimmer housings. Centrifugal models can be quiet too when properly commissioned, but they’re selected primarily for height/pressure. Whatever the type, overall dB(A) depends on intake clearance, nozzle angle, speed staging, and BMS/door-sensor logic (high speed only on door open; standby the rest of the time).

Heated vs Unheated — do I need PTC or hot-water heating in the GCC?

Most GCC entrances run unheated air curtains; the airflow barrier itself provides comfort by reducing hot air infiltration. Heated models (e.g., PTC heating or water heating cross-flow) are typically used in cooler climates, but can be considered in over-cooled vestibules, mixed-mode atriums, or unique seasonal conditions where occupants complain of chill near the door. Prioritize controls/BMS staging before adding heat.

Which type is best for cold rooms, loading bays, and industrial doors?

For cold storage and industrial openings, choose high-pressure centrifugal or specialized cold-room air curtains to maintain a strong, coherent jet and minimize temperature/condensation issues. Expect higher threshold velocities than premium lobbies and confirm against your process/food-safety requirements. Vertical mounting may be considered on very wide doors if specified.

What really drives total cost of ownership (TCO): motor type or control strategy?

Both matter, but controls win over time. EC/VFD efficiencies help, yet the biggest savings come from door interlocks, time-of-day BMS schedules, and correctly tuned nozzle angle/speed—reducing run hours and unnecessary high-speed operation. Keep grilles and fan wheels clean to prevent performance drop-off and rising noise. Document a commissioning baseline dB(A) and floor velocity for ongoing maintenance.

Get Customized Air Curtains for your Project!

Share this post

Related Posts

Best Air Curtain Supplier in Saudi Arabia | Buyer’s Guide

Low Noise Air Curtain | Silent Air Curtains for Hotels & Offices

The Ultimate Guide to Air Curtains in the Middle East

Air Curtain Maintenance Guide –Checklist, Service & Lifespan

Air Curtain Installation Guide – Mounting, Sensors & BMS

Latest Posts

Best Air Curtain Supplier UAE | 2025 Buyer’s Guide

Best Air Curtain Supplier in Saudi Arabia | Buyer’s Guide

Low Noise Air Curtain | Silent Air Curtains for Hotels & Offices

The Ultimate Guide to Air Curtains in the Middle East

Air Curtain Maintenance Guide –Checklist, Service & Lifespan

Air Curtain Installation Guide – Mounting, Sensors & BMS