Best Air Curtain Supplier in Saudi Arabia: A 2025 Buyer’s Guide

How to choose the best Air Curtain Supplier in Saudi Arabia

Saudi Arabia’s entrances work hard. From Riyadh’s Grade‑A offices and five‑star hotel lobbies to Jeddah’s malls and Eastern Province warehouses, doors cycle constantly in hot, dusty, and sometimes windy conditions. Choosing the right Air Curtain Supplier determines whether your threshold stays comfortable, quiet, and energy‑efficient—or becomes a recurring source of drafts, noise, and rising kWh.

This guide breaks down what a top‑tier Air Curtain Supplier should deliver in the Kingdom: proven product range for KSA mounting heights, quiet operation fit for premium spaces, energy‑saving controls, and responsive after‑sales. You’ll also get a sizing workflow, procurement checklist, and model pointers you can use immediately.

New to fundamentals? Start with the Air Curtains Guide.

KSA Use Cases & Performance Targets

Hotels & Premium Offices (Riyadh, Jeddah, NEOM): Target ≤45–50 dB(A) at ~2 m in lobby “door‑open” operation. Commission to achieve ~2.0–2.5 m/s threshold velocity at the sill so the jet seals without creating complaints about drafts.

Retail & QSR: Footfall is high and doors open constantly; set ~2.5–3.0 m/s at the sill for insect/dust control and stable FOH comfort, with door‑open interlocks to limit runtime.

Industrial & Logistics (Dammam, Jubail, Yanbu): For tall shutters and wind‑exposed bays, select centrifugal units matched to mounting height (~3.5–5.5 m typical). Consider vertical jamb‑mounted pairs on very wide portals.

Cold Storage (food logistics, distribution): Maintain ~2.5–3.0 m/s at the sill; add pre‑start/run‑on timers to purge moisture‑laden air and reduce frosting/condensation.

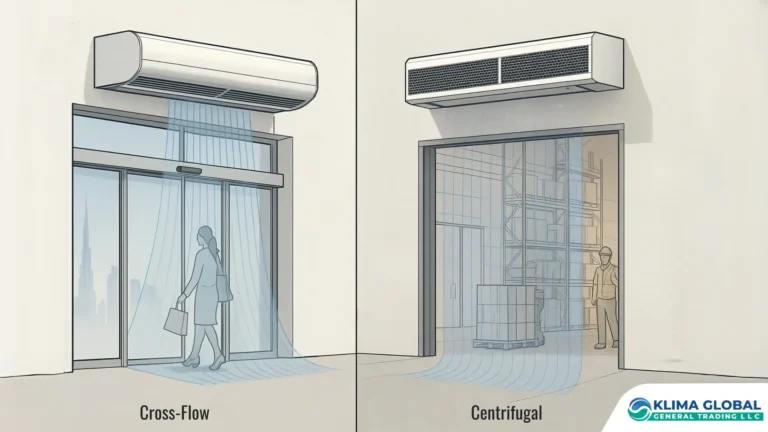

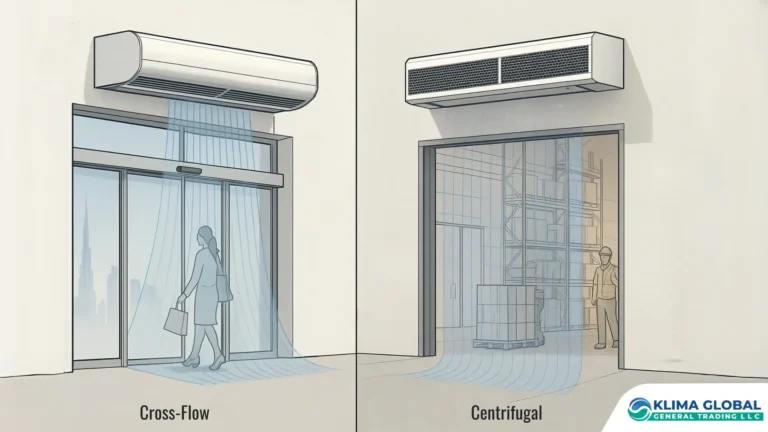

Compare cross‑flow vs centrifugal trade‑offs in the Air Curtain Comparison.

What makes a supplier the “best” in KSA?

A credible Air Curtain Supplier for Saudi projects does more than ship boxes. Look for capabilities that translate into installed performance and lower total cost of ownership:

Complete range & fit: Cross‑flow options for ≈2.3–3.0 m hotel/office lobbies; centrifugal for >3.5 m or wind‑exposed portals; heated/unheated variants where required. Full width coverage options from 900–2000 mm and beyond.

Quiet performance in premium spaces: Rigid, well‑damped casings; guidance on soffit/intake clearance; adjustable deflectors; realistic installed dB(A) targets (not just lab ratings).

Controls & BMS competence: Door sensors, EC/VFD speed staging, and BMS points (run/stop, speed/setpoint, fault). Documented wiring and commissioning procedures.

Energy outcomes: Ability to quantify infiltration reduction and kWh savings; door‑open interlocks, standby speeds, and schedules aligned to operating hours.

Compliance documentation: Submittals, BOQs, O&M manuals, and commissioning checklists that match regional consultant expectations.

Local support: Site surveys, install supervision, spares on the shelf, and response SLAs your facilities team can rely on.

Shortlist options using the Air Curtain Selection Guide.

Recommended product fits by application

Quiet lobbies/offices (≈2.3–3.0 m): Choose low‑noise cross‑flow models with slim profiles and refined finishes—ideal when aesthetics and acoustics matter.

Model I — low‑noise cross‑flow for premium lobbies/reception.

Model K — multiple widths, quiet operation, remote control options.

Model O & Model G — premium casings for design‑led entrances.

Tall/windy/industrial (>3.5 m): Use centrifugal types to maintain a coherent jet at the floor under stack/wind effects.

Cold storage & docks: For chillers/freezers or humid dock doors, select pressure‑capable units with control logic to reduce frosting.

If you are looking for Air Curtain Supplier for your application, Browse the full Air Blade – Air Curtain lineup.

Sizing & engineering workflow for KSA doors

A repeatable workflow keeps projects on schedule and on spec:

Collect inputs: Clear door width, mounting height, door type (sliding/swing/revolving/shutter), cycle rate, wind/pressure exposure, indoor/outdoor ΔT & RH, available power, and BMS readiness.

Select type: Cross‑flow for ≈2.3–3.0 m lobbies; centrifugal for >3.5 m or exposed portals; consider vertical pairs for very wide doors.

Width = door width: Match unit width to the clear opening to prevent edge leakage and whistling.

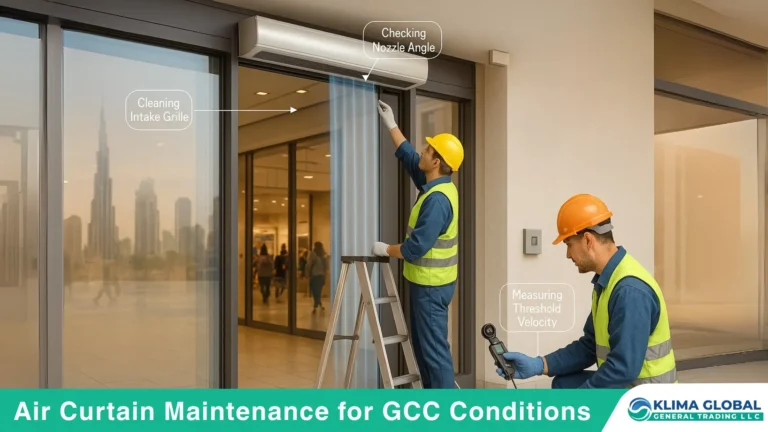

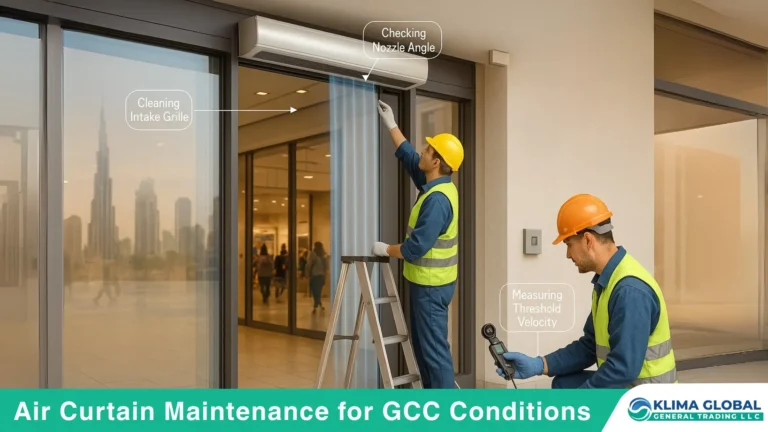

Set initial nozzle angle (0–10° outward): Commission on site under real stack/wind to ensure the jet lands on the sill without bounce‑back.

Verify threshold velocity: Use a 3–5 point anemometer grid across the sill and record ~2.0–2.5 m/s (lobbies/offices) or ~2.5–3.0 m/s (retail/QSR/cold storage).

Log acoustics: Record installed dB(A) at ~2 m in “door‑open” and “standby” states for future maintenance comparisons.

Follow the step‑by‑step Air Curtain Installation Guide.

Controls, BMS & proven energy savings

Controls are the difference between a constant hum and a quiet, efficient entrance:

Door‑open interlock: High speed only on open; standby/low (or off) when closed.

Speed staging with EC/VFD drives: Define low/normal/boost profiles for trading peaks and windy conditions.

Pre‑start and run‑on timers: For shutters and docks, start early and run briefly after closing to stabilize the barrier.

BMS integration: Provide run/stop, speed/setpoint, and fault/status points; align schedules with access control or trading hours.

Measurement culture: Trend sill velocity and installed dB(A); correct drift before it triggers complaints.

Practical strategies are summarized in Energy Saving Air Curtain.

Acoustic excellence for premium KSA properties

A five‑star lobby should feel quiet the second the doors open. Keep acoustics on track by pairing low‑noise models with disciplined engineering:

Rigid mounts & sealed interfaces to avoid panel buzz and bypass whistling.

Intake clearance from bulkheads/signage to prevent hiss and tonal peaks.

Nozzle tuning at handover—often the last 5–10° of angle is the difference between “noticeable jet” and “barely perceptible barrier.”

Door sensors & BMS staging to cut average sound exposure while preserving comfort.

Hospitality specifics are covered in Hotel Air Curtain – GCC.

Sector‑specific guidance & case applications

Retail & Malls: Auto‑sliding doors benefit from interlocks; open‑front concepts often run continuous low speed with a boost profile for peaks. Hypermarkets sometimes need vertical pairs on very wide portals.

Healthcare: Use air curtains at public entrances, cafeterias, and service doors. Avoid compromising pressure regimes for critical rooms; coordinate with the infection‑control team.

Industrial & Logistics: Centrifugal units hold sill velocity under wind/stack effects. Tie to shutter limit switches with pre‑start and run‑on. Consider jamb‑mounted verticals for very wide openings.

Cold Storage: Maintain higher sill velocities and use timers to reduce moist air ingress and frost.

Dive deeper by sector: Retail Air Curtain – GCC • Hospital Air Curtain – GCC • Industrial Air Curtain – GCC • Cold Storage Air Curtain – GCC.

After‑sales, spares & maintenance support in KSA

The best Air Curtain Supplier stands out long after handover. Look for:

Service SLAs that include response times and escalation paths.

Stocked spares (grilles/filters, fan wheels, bearings, sensors) to minimize downtime.

Maintenance cadence: monthly intake cleaning and fastener checks; quarterly sill‑velocity & dB(A) readings with nozzle re‑tune; annual bearing/balance inspection and BMS verification.

Training & documentation so your in‑house team can keep performance on spec.

Use the full checklist in the Air Curtain Maintenance Guide.

Procurement checklist for Saudi projects

When you draft BOQs/RFPs, specify details that guarantee outcomes—not just product codes:

Acoustic performance: Maximum installed dB(A) at a defined distance and operating state.

Geometry & coverage: Design mounting height; door width; requirement for full‑width units or multiples; allowance for vertical pairs if needed.

Performance targets: Sill velocity profile target (e.g., ~2.0–2.5 m/s lobbies; ~2.5–3.0 m/s retail/cold rooms) and adjustable nozzle angle.

Controls & BMS: Door interlocks; EC/VFD speed staging; BMS points list (run/stop, speed/setpoint, fault/status); schedules aligned to hours of operation.

Commissioning deliverables: Velocity readings (3–5 point grid), nozzle angle, installed dB(A), photos/as‑built notes.

Handover package: O&M manuals, training, spare parts list, and periodic service plan.

For design trade‑offs by type and height, revisit the Air Curtain Comparison.

Conclusion & Next Steps

Selecting the right Air Curtain Supplier in Saudi Arabia is ultimately about installed performance: a quiet barrier that preserves lobby comfort, protects conditioned air, and lowers energy use—without calling attention to itself. The supplier you choose should pair a complete product range with engineering rigor, BMS‑savvy controls, and dependable after‑sales so your team spends less time firefighting and more time delighting guests, shoppers, patients, or production managers.

Explore models, sizes, and finishes across the Air Blade – Air Curtain range.

Get Customized Air Curtains for your Project

Proudly serving clients across all major cities of Saudi Arabia, including Riyadh, Jeddah, Dammam, Khobar, Mecca, Medina, Jubail, Yanbu, and Dhahran.

Share this post

Related Posts

Low Noise Air Curtain | Silent Air Curtains for Hotels & Offices

The Ultimate Guide to Air Curtains in the Middle East

Air Curtain Maintenance Guide –Checklist, Service & Lifespan

Air Curtain Installation Guide – Mounting, Sensors & BMS

Air Curtain Comparison – Cross-Flow vs Centrifugal

Latest Posts

Best Air Curtain Supplier UAE | 2025 Buyer’s Guide

Low Noise Air Curtain | Silent Air Curtains for Hotels & Offices

The Ultimate Guide to Air Curtains in the Middle East

Air Curtain Maintenance Guide –Checklist, Service & Lifespan

Air Curtain Installation Guide – Mounting, Sensors & BMS

Air Curtain Comparison – Cross-Flow vs Centrifugal