Air Handling Unit Components and Features

You can examine the air handling unit components and features for the air handling unit models we manufacture.

Check out the air handling unit options suitable for your project.

Framework

The cabinet frame is composed of specially rolled galvanized steel profiles and plastic brackets designed specially for these galvanized steel profiles. Interior surfaces of the profiles are fully sealed in order to minimise pressure loss and avoid aggregation of contaminants inside the air handling unit.

Panel

The panels constituting the body have double layers. The interior surface of the panels is composed of PVC coated or electrostatic painted galvanized sheets. Heat and sound isolation is achieved either by fixing rock wool plates of suitable shape and density into the gap between the layers or by injection of polyurethane. Two component polyurethane injection is mixed and charged between the layers by means of special equipment.

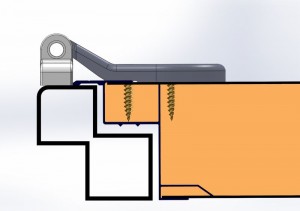

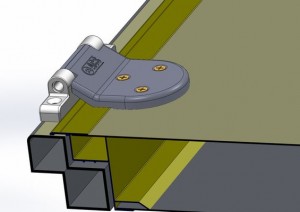

The layers of galvanized sheets are connected via new design K-profiles. Beside serving as fixed bodypanels, the panels can be used as service doors as well.

The panels serving as service doors are equipped with hinges and handle mechanisms of which number differ from 2 to 4 depending on the height of the unit.

The units are equipped with emergency stop button for emergency and another safety switch will stop the operation in case the maintenance lid is open.

Sealing

Special gaskets are used to avoid possible air leakage caused by the pressure difference at the seams where framework and body panels are met.

Fans

In ventilator and aspirator cells; Depending on the pressure loss value in the ventilation system, in systems with low and medium pressure loss (100-700 Pa), backward curved-rare blades, statically and dynamically balanced, high efficiency, silent, double suction, radial NICOTRA brand fans are used. Electric motors. IP 54 protected, F insulation class. 380 V and 50 Hz. dir and is selected according to the value obtained by increasing the safety coefficient of the power drawn by the fan shaft.

Radial fans and electric motors are mounted on the same chassis. Rubber or spring insulators mounted on the carrier slides on the carrier sleds under the fan motor chassis, on the body panel, are used in order to prevent the transmission of the vibration that may occur to the cell. Fan cell outlet and mouth on the radial fan; It is connected with a sealed rubber sealed sheet flanged flexible connection element.

Air Dampers

The air dampers used in the air handling units are made of special self sealing aluminum flaps with hidden plastic gear mechanism and bearing components.

Air dampers provide seamless adjustment for air proportions ranging from 0 to 100% and they are designed according to the air flow rate and unit dimensions to minimize air leakage at the edges. Optionally, dampers can be controlled manually or by a servo motor.

Heater and Cooler Exchangers

Heater and cooler exchangers can be composed of either copper pipe and aluminium fins or steel pipe and steel fins depending on the purpose of the component and type of the fluid. All exchangers are subjected to pressurised hydrostatic test upon completion of the production. Exchangers are installed on the studs arranged in a way to enable easy access and maintenance. Cooler exchangers are equipped with a stainless steel trays or a specially formed PVC droplet catcher for condensing water.

Electric heaters are produced using steel pipe and steel fins with optional safety thermostat.

Filters

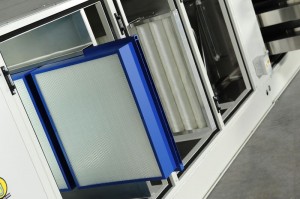

Depending on the requirements various types of filters are used in the air handling units. Class G4 frontal filters are used to catch coarse dust particles and they are arranged in V-form in order to keep the air speed at minimum over the filter.

Class F5, F6, F7 and F9 synthetic bag filters have high dust removal capacity and they are installed in air handling units in the form of cartridges enabling the easy installation and dismounting. Cartridges are composed of specially designed galvanized sheet frame with rubber gaskets.

Filter cell structure is designed to avoid unwanted air leakage and complies to international filter dimensions and optimum air speeds. All filter cells are equipped with a lid providing easy access for replacement and cleaning. Optional differential pressure indicators are available to monitor the clogging of filters.

Heat Recovery unit

Diagonal flow heat recovery unit is composed of aluminium plates. As a result of the high coefficient of heat transfer and large surface area, the unit provides an effective heat transfer between the fresh air coming in and the discharged air going out of the air handling unit. The optimum solution for each system is achieved through consideration of summer and winter design temperatures and operational aspects.

Steam Humidifiers

Steam humidifiers are composed of following components:

- Fittings for steam distributors. The fittings are available in various dimensions and numbers depending on the capacity and are installed in the cabinets built of standard panels.

- Hard PVC monitoring glass.

- PVC and stainless steel droplet catchers to avoid drift of water.

Silencers

Silencers are designed to absorb noise to reduce it to a required level. They are available in the form of compartments that are composed of galvanized frame with glass wool filling covered by a glass fabric.

- Flanged galvanized sheet body, optionally available as stainless steel

- Silencer chamber with glass wool fill and glass fabric cover

- Custom dimensions available

- Rock wool isolation option

- n case of large duct cross-sections, reinforcement traverses are used to achieve high strength and low resonance.

- Class A2 non-combustive fill material conforming to DIN 1402 norms.